Image courtesy of IperionX Ltd.

Charlotte, North Carolina-based titanium metal producer IperionX Ltd. has achieved the UL Environmental Claim Validation Procedure 2809 for its 100 percent-recycled, low-carbon titanium metal powder.

UL Solutions, Northbrook, Illinois, is a global leader in sustainability standards. IperionX says its low-carbon titanium is the first commercial titanium metal powder for additive manufacturing to achieve UL validation for 100 percent-recycled content.

RELATED: IperionX wins US Air Force titanium recycling challenge

IperionX adds that UL recycled-content validation is important as titanium metal powder for additive manufacturing can only be used a limited number of times before quality is affected by contaminants or inferior powder morphology. Additionally, out-of-specification titanium powder increases the probability of defects that jeopardize the structural integrity of additively manufactured components.

The company says titanium metal produced by the standard Kroll process is energy-intensive, high cost, high carbon and is hindered by low levels of circularity. The current manufacturing process for titanium products generates large volumes of scrap that is downcycled to the ferrotitanium market or shipped to landfill.

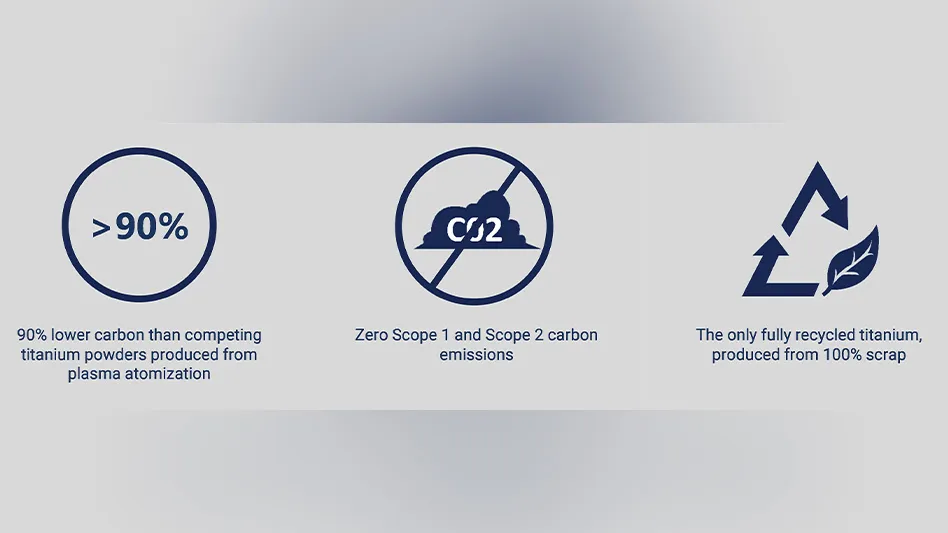

In contrast, the company says its titanium is low-carbon with zero Scopes 1 and 2 emissions, and it can uniquely use 100 percent-scrap titanium as feedstock to produce high-performance, low-carbon recycled titanium metal via a circular supply chain that doesn’t rely upon mined resources.

IperionX recently completed a life cycle assessment (LCA) for its titanium, which it says confirmed its titanium has the lowest quantified life cycle carbon footprint for commercial titanium powder, with a potential life cycle carbon footprint of 7.8 kilograms of carbon dioxide equivalents (CO2e) per kilogram. The company adds this forecasted carbon footprint is more than 90 percent lower than competing titanium powders produced from plasma atomization, 80 percent lower than from titanium ingot produced from the Kroll process, more than 50 percent lower than aluminum ingot and near equal to stainless steel ingot.

“We are very pleased to achieve UL validation for IperionX’s 100 percent-recycled titanium powder,” IperionX co-founder and CEO Anastasios Arima says. “This independent validation recognizes the sustainability performance of our titanium versus competing metal products. In combination with the results from our life cycle assessment, UL validation indicates that IperionX has the lowest carbon, 100 percent-recycled titanium metal on the market. “

The company recently won the U.S. Air Force Research Laboratory Grand Challenge to produce high-quality titanium metal powder from only titanium scrap feedstocks.

Latest from Recycling Today

- Pure Loop celebrates ISEC shredder-extruder at NPE

- New Alpla PET wine bottle cuts carbon emissions

- Ascend Elements, Call2Recycle to offer customized EV battery services

- Novelis quarterly, full-year net sales down; CEO reports ‘strong improvements’

- Meeting the decarbonization challenge

- Cyclic Materials expands leadership team

- Paper cup acceptance at US mills reaches new milestone

- EPA announces $3B to replace lead service lines