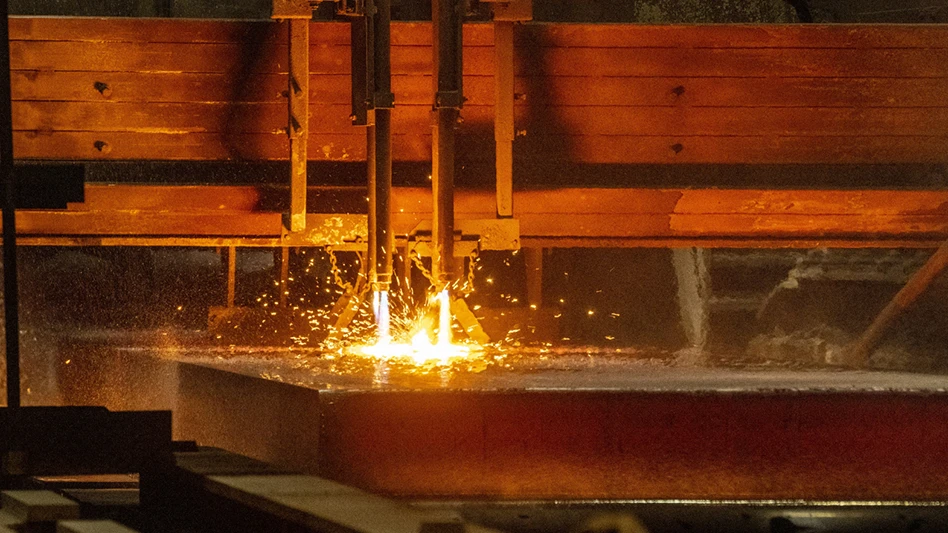

Photo: Aalto University

Researchers at Aalto University in Finland have discovered that cobalt-containing electrodes used in lithium batteries can be reused after being newly saturated with lithium. Compared with traditional recycling, which typically extracts metals from crushed batteries by melting or dissolving them, the new process saves raw materials, and likely also energy, the researchers say.

‘In our earlier study of how lithium cobalt oxide batteries age, we noticed that one of the main causes of battery deterioration is the depletion of lithium in the electrode material,” says Professor Tanja Kallio at Aalto University. “The structures can nevertheless remain relatively stable, so we wanted to see if they can be reused.”

Rechargeable lithium-ion batteries have two electrodes between which electrically charged particles move. Lithium cobalt oxide is used in one electrode and, in most of the batteries, the other is made of carbon and copper.

In traditional battery recycling methods, some of the batteries’ raw materials are lost, and lithium cobalt oxide turns into other cobalt compounds, which require a lengthy chemical refinement process to turn them back into electrode material, researchers at Aalto University say. The new method instead replenishes the spent lithium in the electrode through an electrolysis process, allowing the cobalt compound to be directly reused.

The results show that the performance of electrodes newly saturated with lithium is almost as good as that of those made of new material. Kallio says the method would work on an industrial scale with additional development.

“By reusing the structures of batteries, we can avoid a lot of the labor that is common in recycling and potentially save energy at the same time,” she says. “We believe that the method could help companies that are developing industrial recycling.”

The researchers next aim to see if the same method also could be used with the nickel-based batteries of electric cars.

The research was published in ChemSusChem journal.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Latest from Recycling Today

- NDA unveils workforce toolbox

- Ineos Styrolution launches sour cream cups made with recycled PS

- Lacerta products receive PCR certification

- Trash Pandas Utah launches dumpster rental service

- Vesper added to ReMA’s ISRI Specifications

- Comstock purchases equipment for commercial-scale solar panel recycling site

- LKQ to sell its self-service segment

- BMRA: Potential recovered steel export restrictions risk collapsing UK metals recycling industry