Quality always has been a concern for the recycling industry, and 2017 was no exception. China issued import bans on specific scrap commodities and specifications for incoming material that are more stringent in terms of contamination than standards that are accepted globally. As a result, U.S.-based recyclers shipping commodities to China faced potential rejections or were forced to landfill material typically destined for export.

Equipment suppliers to the recycling industry have kept up with these demands for cleaner quality in the last year, introducing products designed to help recyclers clean up recovered fiber, metals

Robots have made their way into material recovery facilities (MRFs) in the U.S. Recyclers using these systems report cleaner commodity streams, more productivity, higher yield per pound and

Collecting data from processing equipment also has been beneficial to recyclers, as being aware of all kinds of day-to-day information can make a difference in quality and efficiency.

Additionally, recyclers have invested in equipment to better sort and refine recyclables, finding the extra steps are worth the additional money made on the back end.

Recycling Today has reviewed our monthly Product Spotlight as well as our website to present a list of new and updated products that have been featured in the last 12 months. What follows is a rundown of some of these equipment unveilings.

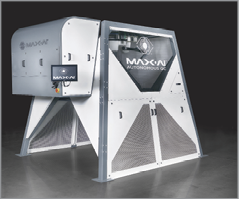

BHS, NRT Max-AI. Bulk Handling Systems (BHS), Eugene, Oregon, and its wholly owned subsidiary NRT, Nashville, Tennessee, have introduced Max-AI, artificial intelligence (AI) designed to identify recyclables and other items. The first machine using Max-AI is an autonomous quality control unit that sorts container streams following optical sorting. Max-AI:

- uses its vision system to see the material, its AI to identify each item and a robot to pick targeted items; and

- can make multiple sorting decisions autonomously at rates exceeding human capabilities.

Visit www.max-ai.com.

Bunting SSSC stainless steel separation conveyor. Bunting Magnetics Co., Newton, Kansas, has introduced its SSSC stainless steel separation conveyor. The conveyor:

- separates work-hardened stainless steel and purifies

zurik fractions; - features a patent pending magnetic grid core design;

- is equipped with a long-lasting urethane belt with 3/16-inch steel side guards;

- is available in custom sizes up to 72 inches wide by 120 inches long; and

- can be equipped with a splitter to separate stainless steel from

nonmagnetics .

Visit https://buntingmagnetics.com.

Cat 988K XE electric drive wheel loader. Caterpillar, Peoria, Illinois, has released the new Cat 988K XE, which it says is its first wheel loader with a high-efficiency electric drive system. The 988K XE wheel loader:

- is designed for demanding job sites where fuel efficiency makes a difference in the machine’s cost of operation;

- offers a range of bucket capacities from 6.2 to 17 cubic yards; and

- increases efficiency by 25 percent overall and by up to 49 percent in face-loading applications when compared with the 988K.

Cofit GorillaBelt. Italy-based Cofit International says it has partnered with Charlotte, North Carolina-based Melt Filtration Products (MFP) to bring Cofit’s postconsumer and postindustrial uninterrupted continuous polymer melt filtration product, the GorillaBelt, to the United States. The GorillaBelt:

- has been running in multiple installations and handling inbound plastic streams with contamination rates ranging from 10 to 15 percent;

- has a throughput rate of 7,000 pounds per hour; and

- has been designed to remove sand, glass, metal, paper, cardboard and

nonmelt polymers.

Visit www.cofit.com.

Eriez Stainless Steel Rare Earth Roll Magnetic Separator. Eriez, Erie, Pennsylvania, has introduced its Stainless Steel Rare Earth Roll Magnetic Separator, which is designed for wire chopping facilities. The unit:

- gives users an option for removing stray stainless steel prior to chopping lines;

- is designed to recover and concentrate stainless steel from the

zurik conductive fraction from a fines minus-1-inch sensor sorting machine or the waste fraction from a fines minus-1-inch eddy current separator; - has a magnetic field strength in excess of 20,000

gauss on the roll surface; and - is the strongest permanent magnet available, preventing damage to the blades on wire choppers.

Visit www.eriez.com.

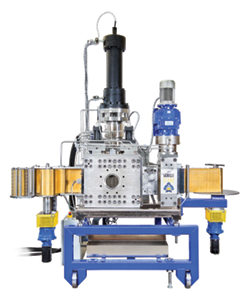

Ettlinger ERF350 filter. Königsbrunn, Germany-based Ettlinger Kunststoffmaschinen GmbH now is offering the ERF350 filter for what it calls “contaminated polymer feedstock.” The company indicates the new model is the first in what will be a “performance-enhanced generation of the ERF series suitable for processing all standard polyolefins and polystyrenes as well as numerous engineering plastics.” The filter:

- can handle styrene copolymers, thermoplastic elastomers (TPEs) and thermoplastic polyurethane (TPU);

- can remove particles such as paper, aluminum, wood elastomers or high-melting polymer composites containing up to 18 percent contaminants; and

- works with a rotating, perforated drum.

Visit www.ettlinger.com.

Genesis GHG 125 handling grapple. Genesis Attachments, headquartered in Superior, Wisconsin, has released its handling grapple, the GHG 125, a 1.25-cubic-yard grapple designed with streamlined features that require less maintenance, the company says. The GHG 125:

- contains a single, oversized cylinder with dual drag links designed to minimize the number of moving parts, simplifying the hydraulic system; and

- is designed for waste handling and recycling, construction and demolition material handling and sorting and primary demolition applications.

Lindner Micromat HP model shredders. Austria-based Lindner-Recyclingtech has introduced its Micromat HP (High Performance) model shredders, which it calls “extremely efficient universal shredders for processing plastics and other [materials].” The Micromat HP shredders:

- are available in sizes and technology similar to Lindner’s existing Micromat 2000 and 2500 systems;

- feature increased

output of up to 30 percent because of the HP upgrades incorporated; and - can be flexibly configured

to any desired purpose.

Visit www.l-rt.com.

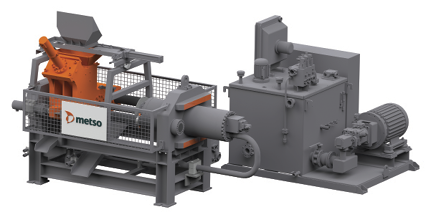

Metso N Series NSP

- produce firmly packed, high-density briquettes;

- increase metal recovery by enabling more accurate metering and reducing burn-off during melting; and

- can be used independently or integrated into various processing plants regardless of size.

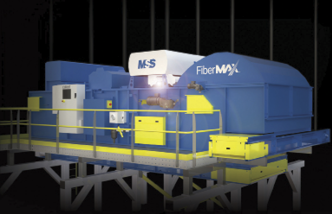

MSS Cirrus FiberMax. Nashville, Tennessee-based MSS Inc., the optical sorter division of the CP Group, San Diego, has introduced its

- a belt that runs at twice the speed of conventional optical sorters;

- a proprietary air-assist and material handling system that keeps paper moving through the sensing zone in a laminar flow without turbulence; and

- an intuitive learning algorithm designed to adapt to changes in the material stream.

Visit www.mssoptical.com.

Pallmann Industries PLMW Turbofiner Lynx. Clifton, New Jersey-based Pallmann Industries has introduced the PLMW Turbofiner Lynx, which it says can produce fine rubber powder from scrap tires without adding nitrogen as a cooling agent. It features:

- the ability to produce material as fine as 425 microns, sizes that were not achievable with traditional ambient grinding processes;

- a vibratory feeder or rotary valve that continuously feeds precut material ranging in size from 2 millimeters to 4 millimeters; and

- a solenoid coil or air sifter that removes contamination.

Visit www.pallmannindustries.com.

Tomra

- a sensor combination capable of detecting more material properties at the same point simultaneously to sort more efficiently;

- the ability to separate thin, thick or opaque glass from MSW; and

- an independent background system designed to ensure sorting stability.

Visit www.tomra.com/en/sorting.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the March 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Buy Scrap Software to showcase its software at Scrap Expo in September

- LG details recycling activities

- Algoma EAF is up and running

- Toyota-Tsusho completes acquisition of Radius Recycling

- CATL, Ellen MacArthur Foundation aim to accelerate circular battery economy

- Commentary: Expanded polystyrene is 98 percent air, 2 percent plastic and 100 percent misunderstood

- AMCS appoints general manager for North America

- How tariffs, regulations affect LIBs recycling in US, EU