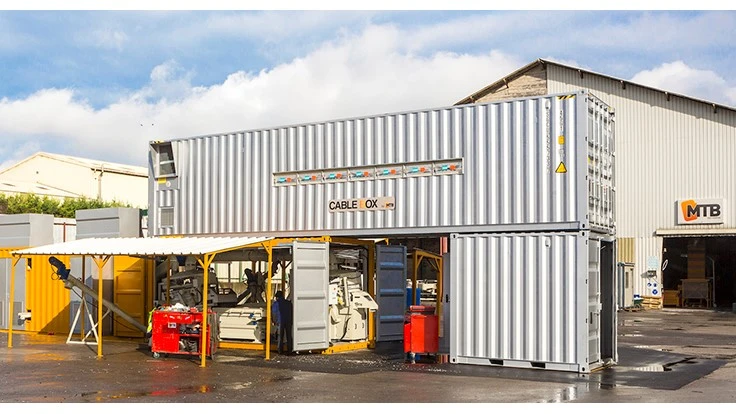

Photo courtesy of MTB Recycling.

The government of the People’s Republic of China may consider imported wire and cable scrap as unwanted “foreign garbage,” but recyclers and metals producers around the world continue to process unwanted scrap wire to harvest the valuable copper and aluminum within.

In the second half of this decade, as China’s government stanches the flow of inbound wire and cable scrap, investments in wire processing Europe, North America and other parts of Asia continue unabated.

The steady roster of projects has allowed equipment companies that offer wire processing technology to revamp, upgrade and fine-tune their machinery and systems, in an effort to provide recyclers with rapid return on investment (ROI) and the with systems that will harvest every last gram of metal.

Not a mystery box

Trept, France-based MTB Recycling both operates a scrap processing facility and designs and makes equipment for the industry.

This decade it has put part of its effort into its “Box” line of processing technologies. In a 2018 conversation with visiting recycling journalist Manfred Beck, MTB Recycling’s owner and CEO Jean-Philippe Fusier told Beck that during some of the slow years in the global economy MTB worked on the Box line.

“These days, people don’t want to wait for months before they get their equipment,” states Fusier. “They want it immediately, want it to be easy to use and installed in next to no time.” He adds that a machine from MTB’s Box line “can be installed in eight hours and it costs 30 percent less than a standard factory installation.”

There are currently several versions of the Boxes, with different units designed to handle cables, tires, plastics, copper, aluminum, e-scrap or auto shredder residue (ASR). MTB’s best seller, according to Fusier, is the Cable Box.

At MTB’s facility in Trept, its large-scale line that processes aluminum cable is housed in a 4,000-square meter (43,000-square foot) building and can process four to five metric tons per hour.

Not all potential customers have such high volume requirements, but with China’s restrictions there is renewed interest in wire chopping in Europe and beyond. MTB has now sold more than 15 Cable Boxes, with several of those sold to the North American market by Wendt Corp.

These units take up 200 square meters (2,150 square feet) yet can still process up to two metric tons per hour, according to Fusier. The Box system contains one shredder, two granulators and a density table.

MTB indicates the acceptance of the Cable Box and other recent innovations is allowing it to expand its manufacturing space in Trept and “triple its production” as part of its MTB 2021 project.

No time like the present

About 1,000 kilometers north of Trept, and across the English Channel, Ipswich, United Kingdom-based S. Sacker Ltd., also known as Sackers Recycling, has opted for a wire processing system made by Denmark based Eldan Recycling A/S.

David Dodds, the company’s managing director, and press releases on the company’s website indicate the firm started off 2019 by ramping up its Eldan system.

Sackers Recycling says the wire processing system “will allow us to process cable at our site rather than selling it on for processing.” Adds the firm, “The machine will run for eight hours per day and will process an incredible 84 kilograms (185 pounds) of cable every minute. Once the copper is processed, it will be sold to customers all over the world, but mostly India and China, [where] it is usually recycled back into more copper cable.”

The U.K. firm describes its new system of consisting of four stages:

- stage one: an Eldan Rasper chops the cable into 10-to-12 millimeter (mm) pieces , and a magnetic belt removes the steel and other magnetic products;

- stage two: a buffer silo spreads the pieces to ensure they are evenly fed into the upcoming granulator;

- stage three: the granulator processes the material into finer pieces of around 4 mm (inches) or less; and

- stage four: a separation table vibrates the processed pieces, using gravity to separate the plastic from the copper.

The company says the Eldan System is part of its larger growth plan and set of action, which has included growing its workforce by 14 percent in 2018, and has resulted in it moving up to No. 53 on a list of “Suffolk’s 100 largest owned and managed businesses” maintained by the East Anglian Times newspaper. Suffolk is the county in England in which Ipswich is the largest city.

Ready for the furnace

United States based metals producer Encore Wire Corp. has taken matters into its own hands when it comes to converting its in-house wire and cable scrap into furnace-ready metal.

The McKinney, Texas-based aluminum and copper wire producer is now using four wire and cable chopping machines supplied by Gold Hill, Oregon-based Sweed Machinery Inc.

Encore Wire has what it describes as “enormous production capacity” to make wire that it distributes in the U.S. But the company’s process engineer Scott Thompson says its scrap processing capabilities lagged behind in sophistication. “We used to have a very labor intensive scrapping process,” Thompson says. “It was a huge labor cost and could potentially pose a hazard to employees.”

At first, the company updated its scrap processing system with a machine from a different equipment manufacturer. “It was a poorly designed and outdated machine,” Thompson says. “The only part of it that worked effectively was a small chopper by Sweed, and it worked really well.”

After considering that, Thompson called Sweed, who he says worked closely with him to understand Encore’s needs, capacity and goals. Four years later, Encore now has three additional Sweed machines customized to its needs, and its scrap processing system has never been more streamlined, according to Thompson.

“Sweed’s machines have exceeded expectations,” he says. Encore uses Sweed’s Model 5703 XHD scrap chopper and PCR 1034 pre-chopper to process linear scrap material. Encore can thus efficiently liberate the copper and aluminum from the products fed into the machines, says Thompson.

Shaker tables further process the PVC, XLPE and nylon plastic coatings by isolating them from the nonferrous copper and aluminum materials to be reclaimed. “We produce and ship millions of pounds of finished product every year,” states Thompson. “A result of manufacturing that much volume is we generate PVC, XLPE and aluminum scrap every year, which diminishes our bottom line.”

Sweed’s machines are enabling Encore to efficiently reclaim reusable raw materials at a lower cost, all while increasing quality and volume of its renewable raw materials internally, according to the company. This increase in material use efficiency and labor savings has resulted in Encore increasing its bottom line.

“It’s a great company,” says Thompson of Sweed Machinery, adding that the firm provides “old school manufacturing that’s down-to-earth and easy to deal with. They’ve got a good way of doing business – just like us.”

Veteran recycling journalist Manfred Beck, who can be contacted at manfredqbeck@gmail.com, contributed to the MTB Recycling section of this article. Josh Francis of Eugene, Oregon-based Revolution Design Group prepared the Sweed Machinery section of the article.

Latest from Recycling Today

- SHFE trading expansion focuses on nickel

- Maverick Environmental Equipment opens Detroit area location

- International Paper completes sale of global cellulose fibers business

- Building a bridge to circularity

- Alton Steel to cease operations

- Nucor finishes 2025 with 14 percent earnings decline

- Algoma to supply Korean shipbuilder

- Improving fleet maintenance management across multiple locations