After extensive beta testing and months of performance validation, Waste Robotics has officially launched the WR4 End of Arm Tool and its AI driven gripper system now generally available to facilities focused on metal sorting and recovery.

“We designed the WR4 to meet the real challenges operators face when dealing with heavy, irregular or tangled metal objects,” says Ziad Akl-Chedid, vice president of product at Waste Robotics. “From day one, our goal was to deliver a tool that not only performs consistently in harsh environments but also simplifies calibration and integration for the teams running it.”

Built for precision in metal sorting

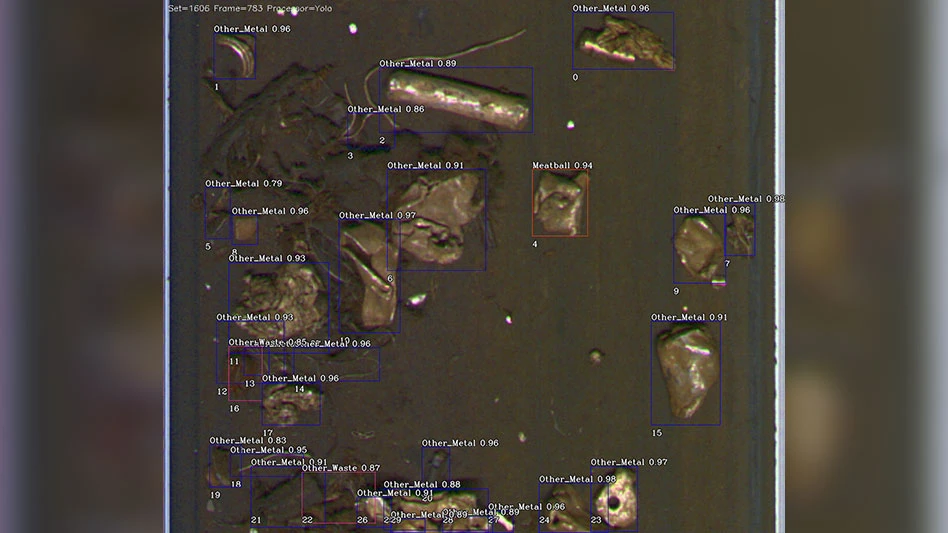

The WR4 system was refined through multiple field deployments in material recovery facilities (MRFs) specializing in metal fractions. Its Pinchr gripper, originally developed for the demanding “meatball” application, is paired with the Fanuc M20 robotic arm, selected for its ideal balance between payload capacity, speed and durability. This combination delivers the robustness required for heavy metal objects while maintaining the agility needed for high-throughput sorting.

The system’s 3D calibration tools now allow operators to define regions of interest when conveyors are uneven or split, ensuring accurate depth references even in variable layouts. In addition, a 2D camera exposure and gain visualization tool enhances optical calibration, allowing technicians to fine tune illumination and color detection directly from the HMI.

“Every update in this release focuses on operator control,” Akl-Chedid explains. “Whether it’s adjusting camera gain in real time or defining a 3D zero reference for nonstandard conveyors, the WR4 gives users more visibility and precision without adding complexity.”

Deployment ready for today’s MRFs

Version 3.7.0 brings WR4 into full support across all Waste Robotics platforms, joining the WR1, WR2, and WR3 families. Each model is purpose built for a specific material stream: WR1 for bag sorting, WR2 for construction and demolition (C&D) material, and WR3 for plastics recovery. With WR4, facilities handling metal streams now have an equally specialized and field-proven system within the same modular architecture.

Facilities running existing Waste Robotics systems can integrate WR4 with minimal downtime thanks to a new dynamic tool parameterization feature that lets users adjust end of arm settings on site without software redeployment.

These improvements are backed by a suite of performance fixes addressing camera synchronization, calibration consistency and system ready signal stability, ensuring the WR4 performs reliably in continuous operation.

Accelerating smarter metal recovery

“We’re seeing a growing demand from MRFs looking to automate metal recovery without sacrificing accuracy,” Akl-Chedid added. “The WR4 meets that demand head on. It’s built to pick intelligently, adapt quickly and deliver consistent performance shift after shift.”

Learn more

Metal recovery facilities and integrator partners interested in deploying the WR4 or requesting a live demonstration can contact Waste Robotics at info@wasterobotic.com or visit https://wasterobotic.com/.

Latest from Recycling Today

- Vecoplan appoints CFO

- Aurubis raises full-year forecast

- Levitated Metals adds LIBS sorting technology

- Redwood Materials closes on $425M in Series E financing

- Updated: Wieland Chase expands northwest Ohio facility

- Recovered paper traders report lukewarm market

- SHFE trading expansion focuses on nickel

- Maverick Environmental Equipment opens Detroit area location