Waste Robotics has released updated information about its recent installations, offering a clearer look at how its systems have been performing in organics, mixed waste and C&D environmentsover the past five years.

The Canadian robotics developer continues to focus on a sensor-based approach that prioritizes material identification over high volume robotic deployment. While automation adoption in waste remains uneven, the company says its aim is to align with how facilities actually operate day to day: inconsistent materials, varying line layouts and limited onsite technical capacity.

Focus on material detection over hardware quantity

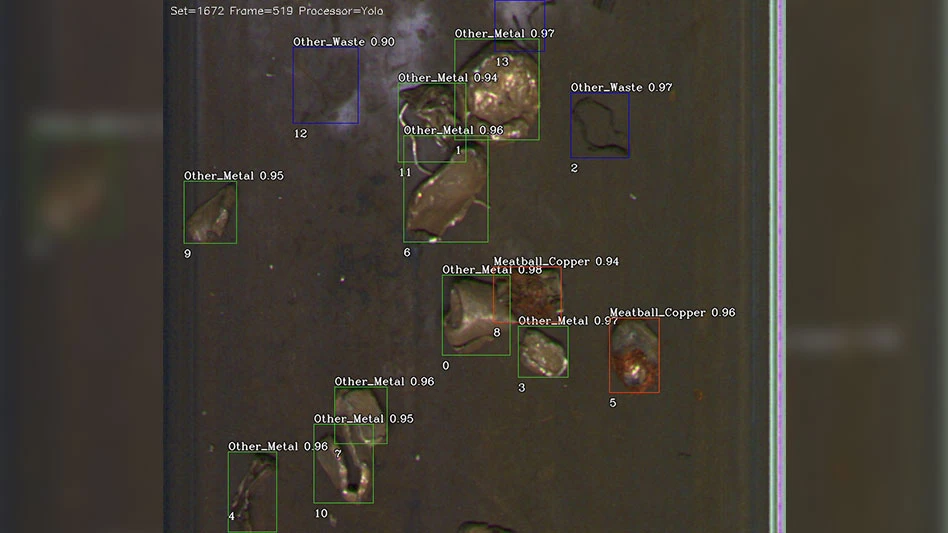

A central piece of Waste Robotics’ strategy has been its use of multisensor setups, including hyperspectral imaging. The company positions this as a practical response to plants where debris is dirty, wet or irregular, conditions that can challenge traditional optical systems.

The AI models are built for each installation rather than standardized across all sites. According to the company, this reduces false identification and helps improve pick decisions in complex waste streams.

Modular systems and maintenance planning

Robotic equipment often enters facilities with concerns around maintenance and long-term service demands. Waste Robotics says its systems are designed around modular builds, simplified part replacement and uptime-focused engineering.

The company notes that most interventions are planned rather than reactive, though full independent verification across the sector is still developing as more facilities gather long term data on robotic performance.

Service support via FANUC network

All robotic arms used by Waste Robotics are manufactured by FANUC, giving customers access to FANUC’s global maintenance network in addition to Waste Robotics’ internal after sales team. According to the company, this structure reduces downtime risks and makes routine service easier for operators who may not have robotics specialists onsite.

Recent images shared by the company highlight technicians working inside active facilities, a reminder that automated systems still require hands-on support to remain reliable.

Performance metrics from the past five years

Waste Robotics shared the following operational metrics:

- More than 30 installations across multiple markets

- Seventy-seven million items recovered through automated sorting

- Forty-four million kilograms in CO₂ reductions attributed to organic waste sorting

- Forty-seven million kilograms in additional CO₂ reductions across broader projects

As with any environmental or performance estimates in the industry, methodology influences outcomes. The company states that these figures are based on cumulative tracking across deployments and will continue to be updated as more data is collected.

Context within a cautious but growing automation market

While robotics interest continues to rise, many operators remain careful when evaluating new systems. Budget constraints, labor shortages and evolving regulatory expectations are shaping how automation is adopted.

Waste Robotics appears to be positioning itself as a provider of specialized, detection driven systems with an emphasis on long term serviceability. As more facilities evaluate automation’s operational value, data focused reporting like this will be important for understanding how these tools perform beyond initial deployment.

Learn more

Metal recovery facilities and integrator partners interested in deploying the WR robots or requesting a live demonstration can contact Waste Robotics at info@wasterobotic.com or visit www.wasterobotic.com.

Latest from Recycling Today

- SHFE trading expansion focuses on nickel

- Maverick Environmental Equipment opens Detroit area location

- International Paper completes sale of global cellulose fibers business

- Building a bridge to circularity

- Alton Steel to cease operations

- Nucor finishes 2025 with 14 percent earnings decline

- Algoma to supply Korean shipbuilder

- Improving fleet maintenance management across multiple locations