Carl Rush has been promoted to vice president, Upstream, and reports to Waste Management President and Chief Operating Officer Larry O’Donnell.

“Our ability to become involved with and impact the customer’s environmental supply chain with comprehensive solutions allows Waste Management to leverage our complete offering,” Rush says. “Our consultative approach of making upstream improvements better aligns us with our customers’ environmental, fiscal and operational goals. Waste Management has always been committed to quality customer service. Upstream further solidifies this commitment.”

O’Donnell says, “This move will help us better align our business goals while providing quality customer service. In order for those efforts to be successful, it’s important to have experienced leadership at the forefront.” He adds, “Carl is a leader in this arena and has a proven track record of high-quality performance. I look forward to the great things that he and his team will accomplish.”

Upstream also provides a platform on which Waste Management can grow its in-pant services business. The In-Plant Services group experienced an average revenue increase of 25 percent yearly from 2002-2004, the company reports.

“The name ‘In Plant Services’ limited the perceived scope of our business,” Rush added. “Our service offering has expanded well beyond on-site management, and we now serve other major generators, like cruise lines and shopping malls. Additionally, we are leveraging our technology to broaden our service offering and bring additional value to the marketplace. This is an exciting time not only for the business, but more importantly our customers.”

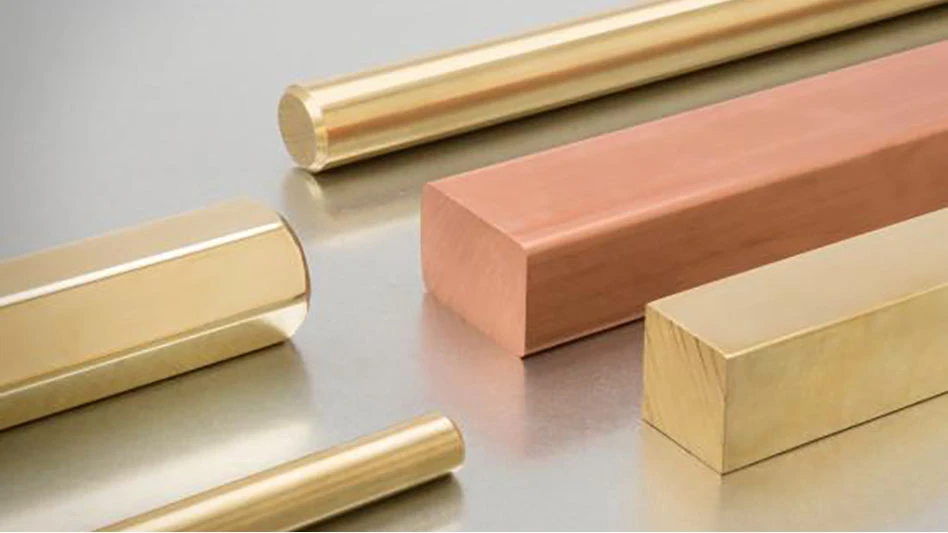

Upstream employs roughly 280 people in plants and facilities throughout the country. Services are offered at 185 different locations. Current industries served include automotive, chemical, refining, metals, food and beverage and cruise lines.

More information about Waste Management Upstream is available online at www.wmupstream.com.

Latest from Recycling Today

- ArcelorMittal finishes 2025 with profitable quarter

- Aurubis earnings drop in late 2025

- Yale feature emphasizes pedestrian safety

- In memoriam: Marcel Braud

- PCA sees improving box demand in latest earnings report

- S&P Global Energy Aluminum Symposium 2026: Debating scrap export policy

- Graphic Packaging CEO: ‘External environment remains challenged near term’

- Recycling Today Media Group, NWRA launch new Safety First webinar series