In what could signal a disquieting change for scrap recyclers, Davie, Florida-based Sintavia LLC has announced it has developed “full end-to-end parameters for producing additively manufactured parts in F357 aluminum, as well as other Al-Si alloys, for use in precision manufacturing.”

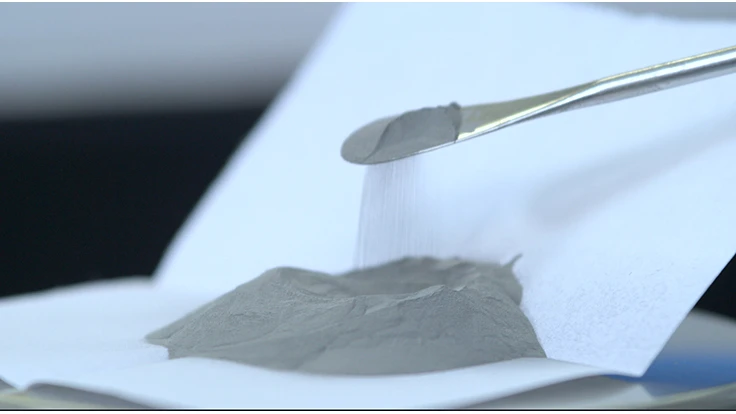

Sintavia says its proprietary process for three-dimensionally printing F357 aluminum powder has been developed “specifically to address aerospace and automotive industry needs for components with low density, good processability and heat conductivity.”

Currently, most aluminum alloy parts are manufactured using traditional casting practices, a process that generates and consumes aluminum scrap. Sintavia says it is “changing the landscape for industries looking to expand beyond traditional manufacturing in foundry-grade aluminum alloys.”

“We are seeing an increased demand for additively manufactured Al-Si (aluminum-silicon alloy) parts from both the aerospace and automotive industries,” says Doug Hedges, Sintavia president and chief operating officer. “With Sintavia’s comprehensive manufacturing capabilities, we have developed processes to make F357 aluminum specimens and quickly test them to demonstrate they meet or exceed these industries’ strict validation parameters.”

Sintavia says its procedure that includes prebuild material analysis and postproduction heat treatment and stress relief “is able to produce advanced manufacturing (AM) components proven to exceed original design strength by up to 125 percent at net densities of near 100 percent.”

The company says aerospace firms and automakers “are demanding — and achieving — reduced cycle times and improved quality from their manufacturing supply chains. Sintavia answers this call for critical manufacturing by leveraging the speed benefits of AM while offering elite powder analysis, postprocessing and mechanical testing on-site.”

Sintavia says its combination of high-speed printers, postprocessing equipment, mechanical testing equipment and metallurgical and powder laboratories allows it “to optimize parameters, serially manufacture and audit quality parts for critical industries.”