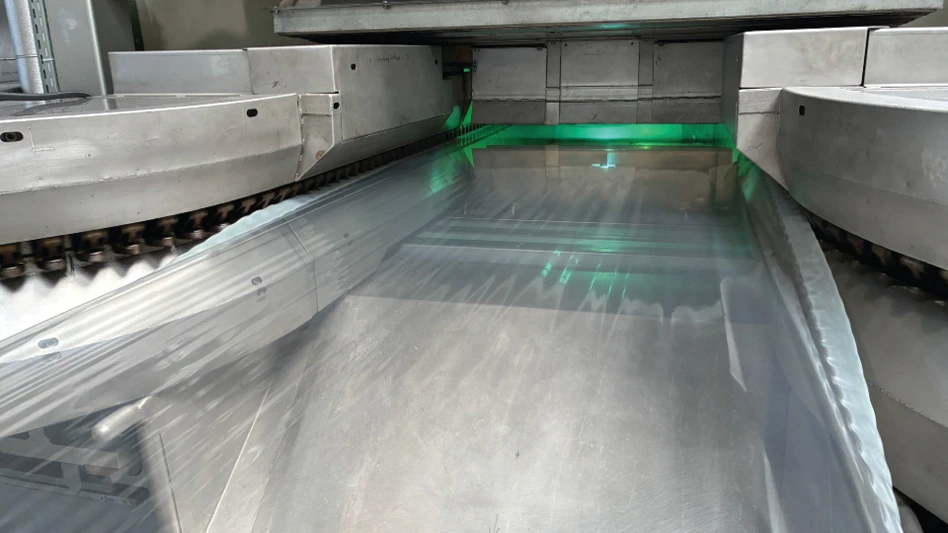

Image courtesy of PureCycle Technologies Inc.

PureCycle Technologies Inc., an Orlando, Florida-based advanced recycler, has announced the completion of larger-scale trials with PureFive resin in biaxially oriented polypropylene (BOPP) film.

The company says 16,000 meters of nearly 1-meter-wide BOPP film of various thicknesses was produced over two days, with the latest trials conducted in August by Germany-based Brückner Maschinenbau GmbH, a supplier of production lines for manufacturing a range of stretch films.

RELATED: PureCycle provides Q2 update

During the trials, PureCycle claims PureFive resin performed similarly to virgin polypropylene (PP) on Brückner’s film line that runs at 40 meters per minute. The trials were conducted with PureFive Choice resin that contained 50 percent postconsumer resin (PCR).

PureCycle says two different types of film were made during the trials. A 25-micron multilayer film was produced with PureFive resin comprising as many as three of the five layers. This type of film commonly is used for food packaging. Additionally, PureCycle says a thicker film of approximately 50 microns was produced for companies that make labels. The film samples now are being shared with potential customers, according to the company.

“We are thrilled by the results of these latest trials with Brückner,” PureCycle CEO Dustin Olson says. “This opens an entirely new application segment for our team for both Ironton and future facilities. Our team has the film in hand, and we are now sharing it with brand owners who can have confidence in running industrial trials at their own facilities.

“I really appreciate the Brückner team for their work on this project. They’ve been incredible to work with, and I know they also see this as a breakthrough for companies around the world that have been looking for a way to introduce PCR content into BOPP film.”

PureCycle notes that BOPP film has a wide range of end-use applications, including food packaging for snacks, candy and baked goods. It also is used for labeling and adhesive tape. The company adds that BOPP films are popular in these applications due to its transparency and moisture and chemical resistance.

“These latest trials with PureFive resin are a big step forward for the industry,” says Dr. Markus Koppers, head of the Technology Center at Brückner Siegsdorf. “PureCycle is proving that a dissolution recycling process can take postconsumer curbside waste and transform it into a recyclate that can perform like virgin polypropylene in applications where the technical properties are incredibly stringent.”

Latest from Recycling Today

- Vermeer announces plan to build new facility in Des Moines metro area

- PureCycle, Toppan partner on packaging containing PCR

- LKQ to focus on simplification, productivity in uncertain demand environment

- Supreme Court strikes down IEEPA tariffs

- Redwood expands San Francisco R&D footprint

- Constellium posts record Q4 adjusted EBITDA

- QCC torches include customizable features

- Umicore finishes 2025 with increased earnings