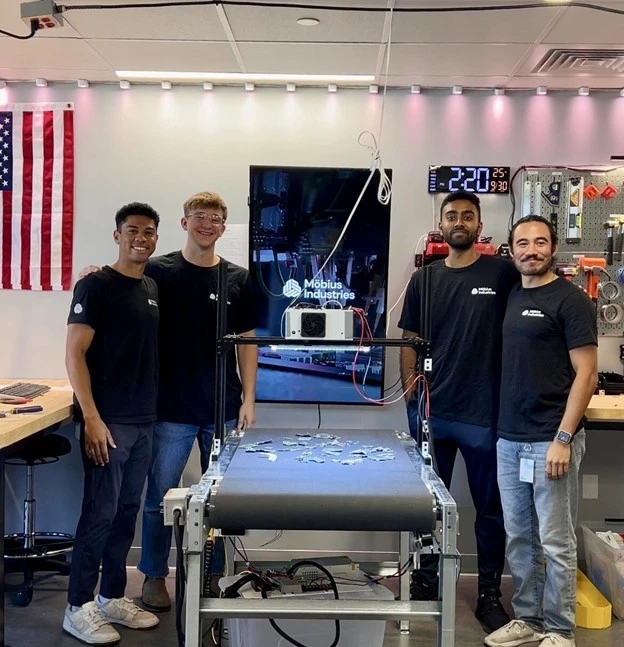

Photo courtesy of Möbius Industries

When Matthew Pierre-Louis founded Möbius Industries in August 2024, his mission was to bring the same level of automation used in manufacturing to the recycling industry.

As a student at MIT, he was studying material science and mechanical engineering, which gave him a perspective on the use of automation in manufacturing. “I realized that recycling is effectively the exact inverse of that,” Pierre-Louis says.

That got him thinking about the recycling industry and why it hasn’t received the same kind of attention from an automation standpoint.

“I think it’s because, for so long, we've been able to bring materials out of the ground and not have to really worry about what happens to them afterwards," he says. "We can landfill things. We could put them to the side. We could send them to other countries and not have to worry about where they go.”

That led Pierre-Louis to reach out to some Boston-area scrapyards to learn more about the industry and its processes. From there, while still a student, he began working directly with a local scrapyard, helping the company revamp its processes. That experience led Pierre-Louis to form Möbius Industries.

“We wanted to challenge the assumption that we're doing the best we can possibly do with the current status quo,” he says. “And I think we've done a really good job at kind of testing those limits.”

He describes his company, where he serves as CEO, as an urban mining company that specializes in demanufacturing. “We want to focus on the domestic production of raw material and allow us to create material sovereignty," he adds.

The company is helping recyclers to upgrade their shredded material.

“We provide the sorting equipment, and we effectively allow you to take what you've already shredded and upgrade that value,” he says. “A lot of times, people have already installed separation techniques, whether it's magnetic at the most rudimentary, or eddy current or optical. What we want to do is basically plug in there and say, we can take this a step further, and you can actually upgrade your material and increase your revenue. That's effectively the sales pitch on our side.”

Pierre-Louis says Möbius Industries is helping recyclers find the fastest, most efficient and least expensive way to upgrade material.

“It's not always going to be a one-size-fits-all solution. Instead, you need to really redesign from the ground up for your process, which is [transforming] product into raw material.

“We have AI [artificial intelligence] engineers working on creating models to actually identify and characterize this type of scrap,” he continues. “And then we also have our mechanics team that's building out the unique hardware.”

Möbius is targeting its solutions for processors of complex material streams such as bulky goods, electronic scrap and construction debris.

“When you look at the characterization of those materials, they are typically higher metal content, typically more complex compared to, let's say, scrap from a manufacturing plant,” Pierre-Louis says. “We actually have a near-unlimited amount of output streams that we can process. And so what that means is that, compared to a machine that currently gives you two outputs, we can give you 5, 10, 15, 20 within a single process. And so that's a huge part of the innovation here.”

He adds that the company is not selling a robot with an arm that is picking and placing but an overall process.

“A huge part of our emphasis is like the mentality of a gigafactory. If you think about Tesla, where they've been able to take a process that usually is done very sequentially, step by step, but now you combine all of them together and you automate it.”

Möbius Industries is scheduling commercial deployments already, Pierre-Louis says. “We want to be that partner of choice for when you want to try something new and you want to see it actually work.”

The company also is developing its ability to assist customers with their operational capabilities.

“What that means is that we're not just a technological provider. … But instead, we can collaborate with people on how you integrate this machine in the best way possible," Pierre-Louis says. "We can give you analytics on how to optimize your process. We have products that are being developed for the analytics, the sorting [and] the processing. Effectively, what we want to do is give you a suite or a family of products that allows you to operate to the best of your capabilities.

“And when you buy into Möbius, you're buying into the ability to see everything that's happening because sensors with AI effectively give you more insight into data that you wouldn't otherwise have.”

Möbius Industries has some customers across the country that are deploying its technology. When those systems are live, they will provide the proof the company needs to expand its installation base, Pierre-Louis says.

In late 2025, Möbius Industries, headquartered in Cambridge, Massachusetts, announced a $3.8 million preseed funding round led by Outlander VC, with participation from Mana Ventures, GoAhead, Entropy Industrial, EWOR, E14, Plug and Play, Thursday Ventures and a group of strategic angels.

The capital will support the company’s deployment of its patented automated AI-driven sorting systems.

Latest from Recycling Today

- Vermeer announces plan to build new facility in Des Moines metro area

- PureCycle, Toppan partner on packaging containing PCR

- LKQ to focus on simplification, productivity in uncertain demand environment

- Supreme Court strikes down IEEPA tariffs

- Redwood expands San Francisco R&D footprint

- Constellium posts record Q4 adjusted EBITDA

- QCC torches include customizable features

- Umicore finishes 2025 with increased earnings