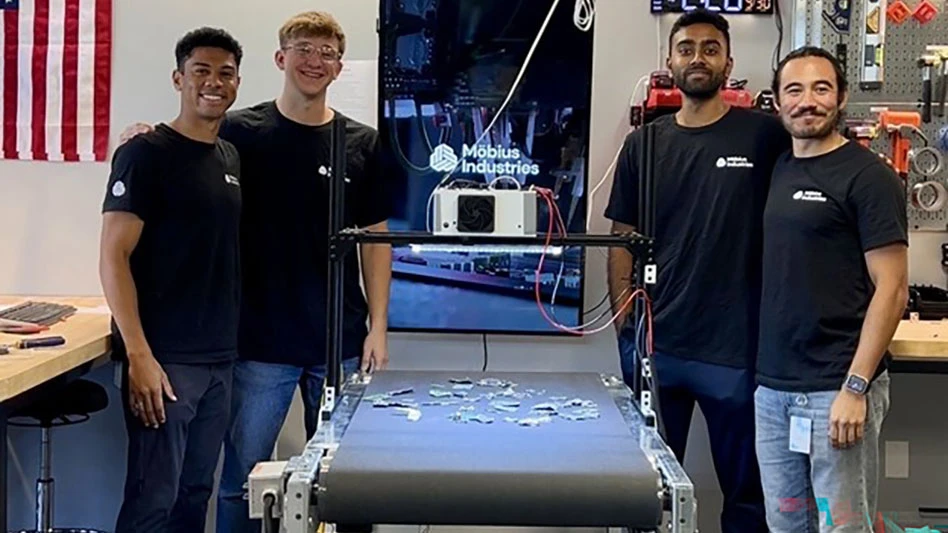

Photo courtesy of Möbius Industries

Möbius Industries, headquartered in Cambridge, Massachusetts, has announced a $3.8 million preseed funding round led by Outlander VC, with participation from Mana Ventures, GoAhead, Entropy Industrial, EWOR, E14, Plug and Play, Thursday Ventures and a group of strategic angels.

The capital will support the company’s deployment of its automated “demanufacturing” and artificial intelligence- (AI-) driven sorting systems that break down end-of-life products to recover high-value metals and plastics in a patented system the company calls “urban mining.”

A circular supply chain

Möbius says it aims to break U.S. dependence on imported materials from traditional overseas mining, building the infrastructure to sustainably transform local end-of-life devices into high-value industrial inputs such as steel, aluminum, copper, cobalt, lithium and other critical components for manufacturing, construction and other industries.

The company says its proprietary process uses less energy and produces fewer carbon emissions than conventional mining and is powered by a first-of-its-kind, full-stack waste conversion system that combines robotics, AI and advanced materials science for seamless, end-to-end automation. Through this system, items are dismantled, sorted and refined into new, industrial-grade raw materials ready to reenter U.S. supply chains.

“The future of mining isn’t in the ground but in our cities," Möbius Industries founder and CEO Matthew Pierre-Louis says. “Möbius is building the infrastructure to convert waste into high-purity inputs for American industry, proving that technology, not geography, determines resource power. With this funding, we’ll scale our technology to deploy at pilot facilities, expand our world-class engineering team and demonstrate that urban mining can eliminate dependence on foreign materials while advancing circularity right here in our own cities and towns.”

The technology

Möbius says its proprietary technology breaks down complex products, including refrigerators, cars, electronics and more, uses a sensing stack to identify dozens of unique metal types, then separates and refines them into distinct streams reaching up to 95 percent purity. This process results in high-quality, reusable materials, without the environmental and geopolitical costs of traditional extraction mining.

“Möbius has engineered a blueprint for the next generation of industrial innovation that we haven’t seen at this level of sophistication or scale,” says Jordan Kretchmer, senior partner at Outlander VC, New York City. “The global demand for critical materials represents a near-trillion-dollar opportunity, and Möbius’ urban mining model directly addresses that need with a scalable, domestic solution. By unlocking value from waste, they’re redefining the economics of resource recovery and supply chain resilience in the U.S.”

Meeting demand

Möbius says its technology recovers resources that are circulating domestically, creating a faster, cleaner, more secure alternative through automated collection, processing, sorting, refinement and distribution. By turning yesterday’s waste into tomorrow’s batteries, automobiles, building materials and more, the company says it helps industries achieve true circularity at home, reducing emissions, shipping costs and resource scarcity.

The company says its technology is poised to fill the immediate need the U.S. has for these resources while avoiding the hurdles and drawbacks of traditional mining, which is resource-intensive and often requires multibillion-dollar investments and decades of development before reaching commercialization (on average 29 years in the U.S. and 16 years globally) as well as geopolitical tensions and global supply chain disruptions.

Latest from Recycling Today

- You have production scrap, WEIMA machinery processes it where it’s made

- CP Group, Cisek Inspections forge innovative X‑ray recycling alliance

- Regroup, CP Group unite for cutting-edge Halifax MRF

- Modern MRFs: AI, automation and safety, redefining recycling operations

- CalRecycle opens comment period on proposed SB 54 revisions

- 2026 Circular Steel Summit: Taking stock of tariffs

- CDRA Conference & Tradeshow 2026: Addressing battery fire risks

- Darda equipment now available in North America