The following is part 1 of a 2-part feature on the importance of adjusting shredding operations depending on market conditions. The feature has been submitted by Metso Lindemann.

The high global demand for steel in recent years had a major impact on the complex supply channels for the raw materials. It is just like a combustible gas being introduced to one end of an air duct system and then ignited. An explosive flame darts through the pipelines. Once the gas is switched off, the advancing deflagration is extinguished and negative pressure is created as the area cools down. A bold simile? Let us examine the market.

The high demand for steel caused steel prices to rise. The prices for ore and coking coal experienced an almost simultaneous increase. Equally the demand for processed scrap steel picked up. Some quantities of scrap were diverted from their traditional channels of distribution and found new customers. During this period steelworks tended to reduce their quality standards for processed scrap metal so that they could procure the required volumes.

|

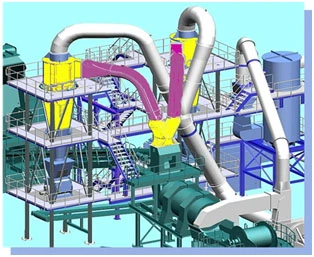

| Decoupled dust removal units for the Zerdirator and the separating drum. |

Shredding plants throughout the world were operating at full capacity. The pull of demand soon reached the scrap metal suppliers. Increasingly the scrap delivered to shredding plants was of an inferior quality and contained higher levels of contamination. The processing plants found themselves in a catch-22 situation. They had to process inferior material while working flat out, which resulted in greater wear, more repairs and therefore longer downtimes. Any companies still producing scrap that exceeded the quality requirements could not expect to be rewarded for their efforts.

Poor scrap being stockpiled

When the demand for steel and the prices for this commodity collapsed, the warehouses were still full of unprocessed mixed scrap, some of moderate quality. This material is still waiting to be processed. The steelworks switched to tightening the quality screws when it came to purchasing scrap. With an excess supply of processed scrap, they can now insist on buying only top grade material.

Shredding plants are the principal interface between supplying mixed scrap and purchasing scrap from the steelworks. The crisis has shown that they have to cope with fluctuations at the upstream end (input) and at the downstream end (output). Contrary to frequent assumptions, the increased value is derived less from crushing the material in the hammer mill, but rather from reprocessing the recovered metal. The profit is generated by sorting the material as carefully as possible into steel scrap, non-ferrous scrap, SLF (shredder light fraction) and SHF (shredder heavy fraction).

The Düsseldorf-based mechanical engineering company Metso Lindemann GmbH has developed its own design philosophy, constructing shredders designed to be flexible, low-maintenance and durable. A complex scenario emerged in an interview with Peter Wilbert, product manager for metal shredders.

De-dusting is split and adjustable

In Metso’s case, Power Zerdirator shredders offer application flexibility and as such are designed to be adjustable so that they can process various grades of steel and aluminum. The adjustability of the de-dusting unit plays a key part in this. In the systems currently produced, the de-dusting process is split. Dust is removed from the Zerdirator’s outgoing air flow in the conventional way using a combination of cyclone and Venturi washer. This system is designed to be resistant to explosion shock pressure. In a decoupled process, dust is removed from the separating drum, where no severe air shocks occur.

There is a strong counter-flow of air in the separating drum, which separates the SLF and also entrains some light sheet cuttings. To break up material compositions and adhesions, the material being processed in the shredder is flung onto baffle plates in free flight as soon as it enters the separating drum. The aim is to achieve an action that inputs the material in a wide-ranging ballistic curve. Efficiency would be reduced if the material were to impact the baffles at one particular point. The counter-flow of air in the drum that also covers the inlet zone passes into a cyclone with a downstream dry filter. A specific trend in material cleaning can be discerned at Lindemann. Traditional air separators are being replaced by the more efficient separating drums, and this currently applies to all models from 1,250 to 7,000 HP. The material is fed into the separating drum at an adjustable speed, quantity and trajectory to suit the specific material being processed.

Light sheet flies away

Contaminated mixed scrap requires the two decoupled dust removal units to deliver superior cleaning efficiency. However, the air flows should not be so strong that any more valuable metal than is absolutely unavoidable is entrained with the SLF. This would also make disposal of the SLF more costly. Consequently the extraction capacity is adjusted using ventilators that are controlled by frequency converters, and using butterfly valves. If scrap aluminum is being processed in the shredder, the air flows in the de-dusting unit have to be restricted. Otherwise too much light metal would enter the SLF, from where it could only be removed with difficulty.

The increased amounts of dirt (contamination) in the scrap result in the wear of some dust removal components and in increased cleaning requirements. Areas particularly subject to intensive wear are therefore lined with special abrasion-resistant materials. In addition, the ventilators are equipped with traversing devices that make them easy to open and to clean. These measures should achieve a marked decrease in the downtimes required for cleaning and maintenance.

During the commissioning of a Lindemann shredder, series of measurements are carried out on site so that the system as a whole can be correctly adjusted. This also involves storing setting parameters for the separate processing of aluminum.

Since the de-dusting units are critical components of the overall system, they are designed by Lindemann and only manufactured by approved sub-contractors. The design process is based on experience gained from 750 industrial shredding plants installed throughout the world. Metso Lindeman

Part 2 of this feature will appear in the April issue of Recycling Today's Auto Shredder Newsletter.

Latest from Recycling Today

- Charter Next Generation joins US Flexible Film Initiative

- Vecoplan to present modular solutions at IFAT 2026

- Terex Ecotec appoints Bradley Equipment as Texas distributor

- Greenwave raises revenue but loses money in Q2 2025

- Recycled steel prices hold steady

- EY says India’s need for scrap imports will continue

- Coming full circle

- Amcor, DCM introduce fertilizer packaging with 35 percent recycled content