Itronics Inc., a diversified zinc fertilizer and silver producing company based in Reno, Nevada, says it has completed temporary installation of its commercial e-scrap grinder and started testing the finely ground material in its refining furnaces. The furnaces are producing between 50 percent and 80 percent more bullion per melt, with variability based on differences in the metal content of the infeed material, the company adds.

“It is exciting to us to see that our theory of the grinding benefits is now being realized," says John Whitney, Itronics president. “We have increased silver production in the second quarter, but the increase in sales will be in the third and fourth quarters due to the long elapsed time between the production of the bullion and completion of bullion sales.”

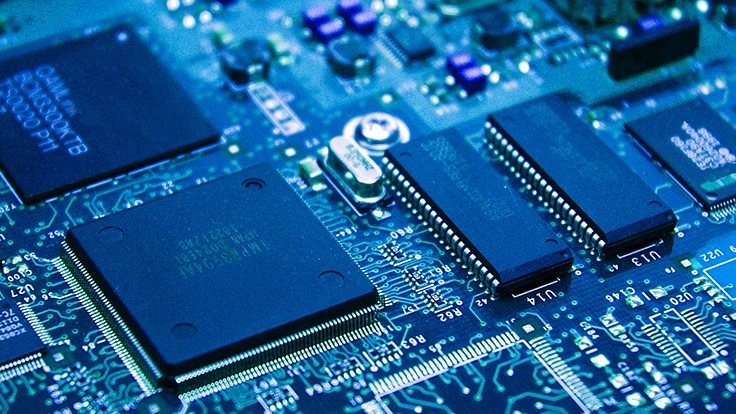

The company’s technology uses silver to extract silver, copper and gold, along with the critical metals (as recently defined by the U.S. Department of the Interior) tin, antimony and palladium, from e-scrap.

Itronics says it is positioned to benefit significantly as silver bullion production is expanded and prices of copper, zinc, silver, gold and palladium increase.

Latest from Recycling Today

- Metals Innovation Initiative announces competition to address problems in Kentucky’s metals industry

- Dow, Mura Technology cancel chemical recycling plant in Germany

- Brightmark, Lewis Salvage partnership processes 1M pounds of medical plastics

- US paper recycling rate, exports down in '24

- Century Aluminum to restart idled production at South Carolina smelter

- Teaching kids the value of recycling

- ELV Select Equipment, Reworld aid NYPD in secure firearm disposal

- Some observers fear plastics treaty talks veering off course