Eldan Recycling A/S

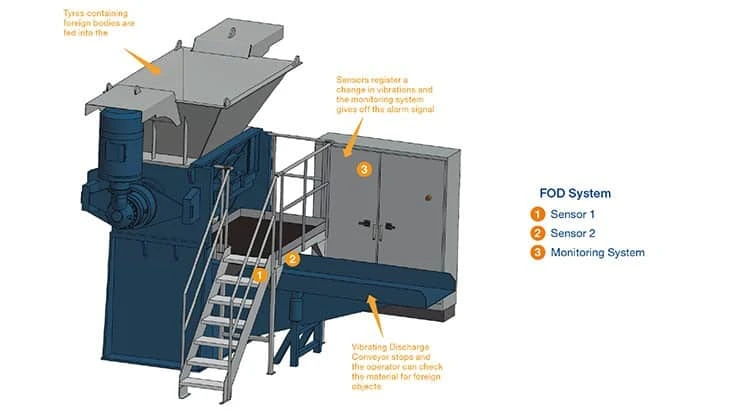

Eldan Recycling A/S, a Denmark-based company focused on developing machinery and methods for making recycling of tires, cables, refrigerators and aluminum more efficient, reports that it has developed a sensor-based system to detect foreign objects in tire shreds and to reduce the risk of breakdowns and downtime.

Eldan’s Foreign Object Detection (FOD) system consists of a sensor system that monitors the vibrating discharge conveyor following the Eldan Super Chopper. Changes in acceleration from dense objects hitting the surface are picked up by the FOD system, which will stop the material flow of the plant and give off a warning signal. It is then easy for the operator to search through the material on the vibrating discharge conveyor, find the foreign object, remove the foreign object and continue production, according to a news release from Eldan on the FOD system.

“We have run the system for more than nine months at a customer’s site to test the efficiency and are very satisfied with the results so far,” says Jan Kjær, head of research and development at Eldan. “A breakdown is expensive both in terms of downtime and spare parts, but even the most thorough cleaning of the tires cannot remove all the foreign objects that may hide inside. This system will serve as an extra safety measure to protect the following machines.”

To prevent a false sense of security, the system comes with a backup safety system in case one of the sensors fails. Eldan Recycling says it can run with just one functioning sensor but will give off a warning signal. If both sensors fail, the plant will stop.

Eldan Recycling says its FOD system can detect small and large metal objects and stones, adding that the sensors can be adjusted to meet specific customer demands.

“We are currently developing the system for other types of input material too” such as cables, Kjær says. “The plan is to start testing with a customer soon.”

Latest from Recycling Today

- Super Bowl LX will implement reusable cup program, AI recycling systems

- ArcelorMittal finishes 2025 with profitable quarter

- Aurubis earnings drop in late 2025

- Yale feature emphasizes pedestrian safety

- In memoriam: Marcel Braud

- PCA sees improving box demand in latest earnings report

- S&P Global Energy Aluminum Symposium 2026: Debating scrap export policy

- Graphic Packaging CEO: ‘External environment remains challenged near term’