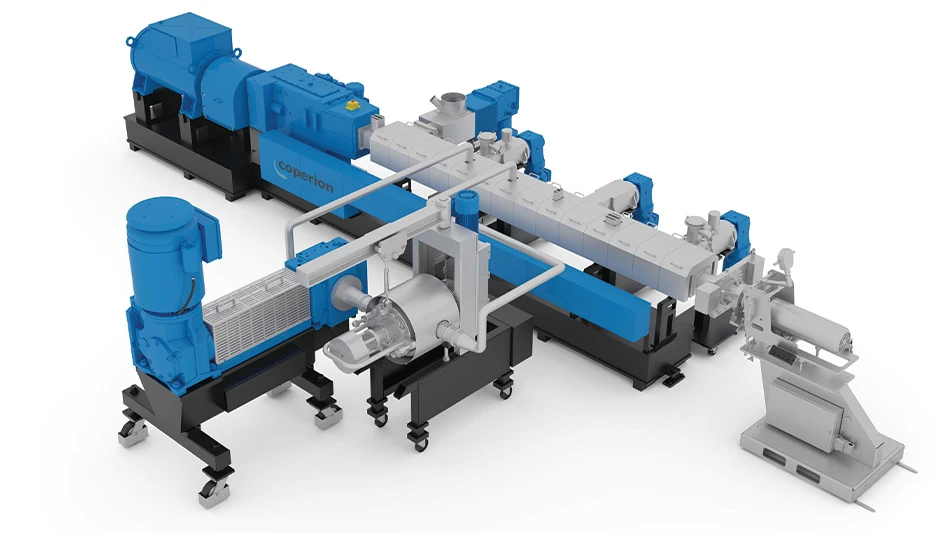

Image courtesy of Coperion

German equipment manufacturers Coperion and Herbold Meckesheim will present their expertise in various plastics recycling applications at this year’s K Show, taking place in Dusseldorf, Germany, Oct. 8-15.

According to Coperion, Herbold equipment designed for mechanical plastics processing will be on display at Booth 9B34 in Hall 9, including its new T 150-300 mechanical dryer and the SMS 80-200 granulator.

In the open area, Pavilion FG/CE07, attendees will be able to see the interplay of all Coperion recycling technologies. The company will display Herbold’s ZSK FilCo filtration compounder, the ZS-B Megafeed side feeder, a Coperion K-Tron K3-V200 vibratory feeder, an S60 single-screw feeder and the MechaTron flat bottom feeder. Also on display will be a mobile deodorization unit for reliably removing unpleasant odors from recycled materials.

“In addition to plastics recycling, Coperion specializes in plastic compounding technologies,” the company says. “These core competencies will be on display at Booth 14B19 in Hall 14.”

Focus on performance

In Pavilion FG/CE07, Coperion says it will exhibit its new ZSK FilCo filtration compounder which enables recyclable materials filtering in and subsequent compounding in one step. In comparison to two-step production lines, the company says the ZSK FilCo handles the product “very gently” and provides higher quality at significantly reduced energy consumption when recycling postconsumer scrap and other highly contaminated polymers.

Coperion says plastic scrap in the form of regrind, fiber pellets, film flakes or agglomerate with no pretreatment are introduced into a ZSK twin-screw extruder, where they are melted, homogenized and devolatilized. The melt then is fed through a filter, removing any contaminants. In the subsequent compounding process, additives are introduced into the melt prior to pelletizing the compound.

Coperion says that to “fully exploit” the machine’s performance, raw materials must be supplied at a constant rate with no intake limits. “While this can be accomplished either by pelletizing the waste plastic or regrind, or by using a compacting process, these are very energy-intensive processes and increase both capital and operating costs,” the company says.

In contrast, Coperion claims that its ZS-B Megafeed side feeder, also scheduled to be on display at the pavilion, feeds recycled materials with a bulk density as low as 20 kg/m3 into the ZSK FilCo and other ZSK extruders, allowing for recycling and compounding of lightweight, high-volume fibers and flakes at high throughputs.

Connecting bulk material handling, feeding technology

In the pavilion, Coperion will display its K-Tron K3-V200 vibratory feeder that it says provides high-accuracy gravimetric feeding particularly for challenging materials, such as where smaller recyclables or flakes are being fed into the extrusion process. For “light and fluffy,” hard-to-feed materials such as polypropylene (PP) or polyethylene terephthalate (PET) plastic film, Coperion says it will showcase its MechaTron FB (flat bottom) feeder, a gravimetric feeder ideal for high-capacity recycling operations. Also on display will be Coperion’s K-Tron S60 single-screw feeder.

Coperion says it developed its ZRD rotary valve especially for plastics recycling processes. “Together with the new drive technology, the new design of the gap between the rotor and housing ensures reliable discharge of flakes.”

At K 2025, Coperion says it will demonstrate how its various technologies work together through an all-encompassing 3D simulation. Attendees will be able to gain insights into the operation of a complete system as well as the function of each individual component.

Latest from Recycling Today

- Stadler equips Spanish MRF

- SSAB finishes 2025 with decreased revenue

- Vecoplan appoints CFO

- Aurubis raises full-year forecast

- Levitated Metals adds LIBS sorting technology

- Redwood Materials closes on $425M in Series E financing

- Updated: Wieland Chase expands northwest Ohio facility

- Recovered paper traders report lukewarm market