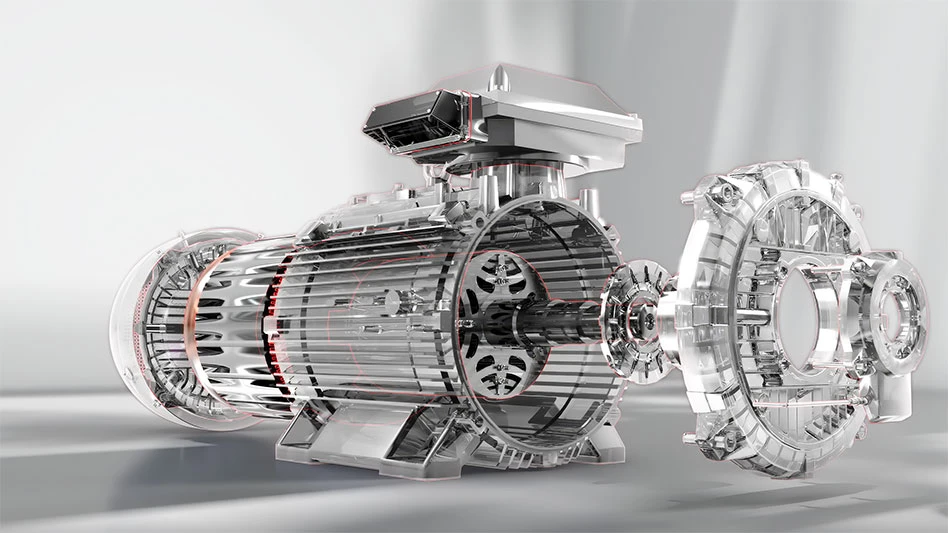

Photo courtesy of ABB

Every year, Earth Overshoot Day reminds us that we’re living in ecological debt. In 2025, that day falls on July 24, and it tells us that humanity already has consumed more natural resources than our planet can regenerate for the year. For energy-intensive industries like manufacturing, where supply chains run long and carbon footprints often cast a global shadow, it’s a timely wake-up call.

If we’re serious about turning the tide on resource overshoot, we must do more than recycle aluminium cans and paper cups. We have to think in kilowatts generated and in tons of raw materials used to change how we design, build and retire industrial equipment like electric motors. This is where circularity steps in.

The case for circular design

Electric motors are a hidden opportunity for sustainability, and circular design is starting to show real promise.

At Zurich-based ABB, our electric motors are built mostly from metals, designed to be up to 98 percent recyclable—with the remaining 2 percent recoverable through heat-generating incineration—and capable of lifespans stretching more than 15 years. But just because we're starting from a strong baseline, it doesn’t mean we’re standing still.

Take a motor’s life cycle emissions as a starting point. Traditionally, the industry has focused on energy efficiency in operation—which still matters as nearly 97 percent of a motor’s total cost of ownership is tied to electricity consumption over its lifetime. But, today, that view is expanding to encompass the full life cycle: from raw material extraction to usage and end-of-life recycling.

Integrating sustainability into product development, from start to finish, is becoming an industry imperative. At ABB, we use a structured life cycle approach to analyze environmental impact at the design phase and incorporate low-carbon material alternatives to balance performance, efficiency and material use—all without compromising performance.

To properly quantify environmental impact, internationally recognized frameworks such as ISO 14040 and ISO 14044 are key. Their application creates a valuable common language for sustainability, enabling more transparent benchmarking and informed decision-making across the supply chain. And when combined with commercial life cycle assessment (LCA) software, they help engineers translate sustainability targets into tangible design choices at critical development phases.

Materials matter

The materials chosen for a motor can make or break its sustainability credentials. We’ve worked closely with our suppliers to source and integrate more sustainable materials, starting with a new low-carbon electrical steel (e-steel). Produced using renewable energy and process innovation on the factory floor, this next-generation e-steel boasts a 40 percent lower carbon footprint than regular steel.

We’ve implemented similar material choices in other components, including a shaft made with up to 99 percent recycled steel that already is in use in select motor ranges and supported by supplier documentation and life cycle assessment data verifying its reduced carbon footprint. We’re also collaborating with Boliden, a Swedish mining and smelting leader, to source low-carbon and recycled copper for our IE5 synchronous reluctance (SynRM) motors.

Considering that a typical 75-kilowatt motor weighing 650 kilograms, or more than 1,400 pounds, might contain around 80 kilograms, or roughly 176 pounds, of copper, using Boliden’s copper saves approximately 200 kilograms (441 pounds) of carbon emissions per unit. And its impact isn’t theoretical. More than 5,000 motors have been built with this low-carbon copper, saving roughly 1,000 tons of carbon emissions. As it turns out, cleaner copper packs a serious punch.

Suppliers as sustainability partners

Of course, circularity doesn't begin or end at the factory gate; it hinges on transparency and collaboration throughout the entire supply chain. At ABB IEC Low Voltage Motors, we recognize that designing for sustainability is only possible when the materials we use in our products are being handled responsibly from the very start. That’s why we view our suppliers not just as vendors but as sustainability partners.

Our role isn’t to dictate how things should be done but to raise the bar together. At ABB, our supply chain management team plays a central role in leading this push toward sustainability. The team leads regular innovation workshops with our suppliers to explore low-carbon material strategies and map out a path for their implementation. These discussions span everything from maximizing recycled content and evaluating alternative feedstocks to brainstorming cleaner production methods.

Crucially, these conversations are not academic; they directly shape the materials we source and use. At ABB, we're constantly thinking of ways to embed sustainability into every layer of design, even down to the raw materials themselves.

Sustainable design, proven in practice

There's a common misconception that going green means compromising on durability or cost, but this couldn’t be further from the truth. When designing our prototype circular motor, we pushed the boundaries of integrating low-carbon materials—e-steel, recycled copper, low-impact bearings—and the results were surprising. Not only was performance uncompromised, but we modeled a potential 60 percent cradle-to-gate carbon footprint reduction for the SynRM design. All without compromising lifespan or mechanical performance.

Every material incorporated, regardless of its recycled content, must meet ABB’s quality and performance standards. Variations in recycled material purity can directly affect the strength, thermal stability and other performance metrics of components. Our suppliers meet stringent specifications, often backed by environmental product declarations (EPDs) and third-party audits, and all materials are validated through rigorous lab testing. Each design iteration also gets a full stress test during internal prototype evaluation to ensure it can perform under pressure.

Closing the loop responsibly

When a motor reaches the end of its life, our goal is to ensure it reenters the raw material loop rather than wasting away in a landfill. Circularity in practice means that motors are broken down into components—housing, stator, windings and rotor shaft—and processed separately, typically by crushing and smelting. At ABB, the loop is already closing. Metals like copper and aluminum recovered by smelters are reentering our supply chain as raw materials for new motors, reducing the demand for virgin extraction. The process is not without its challenges—for example, rare-earth metals often end up mixed during recycling—but the potential is undoubtably there.

To go a step further, ABB has established motor take-back and recycling programs in several countries. These schemes reduce the risk of unregulated refurbishment practices, causing motors to reenter the market with compromised safety or performance capabilities. Verified recycling channels help improve data tracking and prevent safety issues, the latter of which is naturally a bigger risk with older motors. Through ABB’s take-back initiative, we ensure that retired motors are properly recycled rather than discarded, exported or forgotten. That’s what we call responsible circularity in action.

Earth can’t wait, and we don’t have to

Earth Overshoot Day lays bare the fact that the planet can no longer afford a linear economy of “take, make, waste.” The clock is running out on extractive, throwaway mindsets. To make progress toward net zero targets, industry must embrace the loop of reuse, recovery and reinvention. And the electric motor, as universal as it is reliable, can be the flag bearer.

At ABB, we’re not just making motors. We’re building a system where sustainability sits at the center of everything, from selecting low-carbon e-steel and copper, to validating emissions data, to closing the circle at end-of-life with recycling and take-back programs.

Modern engineering doesn’t have to choose between durability, performance and environmental responsibility. With the right design methodology and collaboration from everyone along the value chain, we can have all three.

Ghanshyam Shrestha is R&D technology manager at ABB IEC Low Voltage Motors, and Santanu Singha is R&D sustainability manager at ABB IEC Low Voltage Motors. The company is headquartered in Zurich and can be reached through https://global.abb/group/en.

Latest from Recycling Today

- SSAB finishes 2025 with decreased revenue

- Vecoplan appoints CFO

- Aurubis raises full-year forecast

- Levitated Metals adds LIBS sorting technology

- Redwood Materials closes on $425M in Series E financing

- Updated: Wieland Chase expands northwest Ohio facility

- Recovered paper traders report lukewarm market

- SHFE trading expansion focuses on nickel