Image courtesy of Borealis GmbH

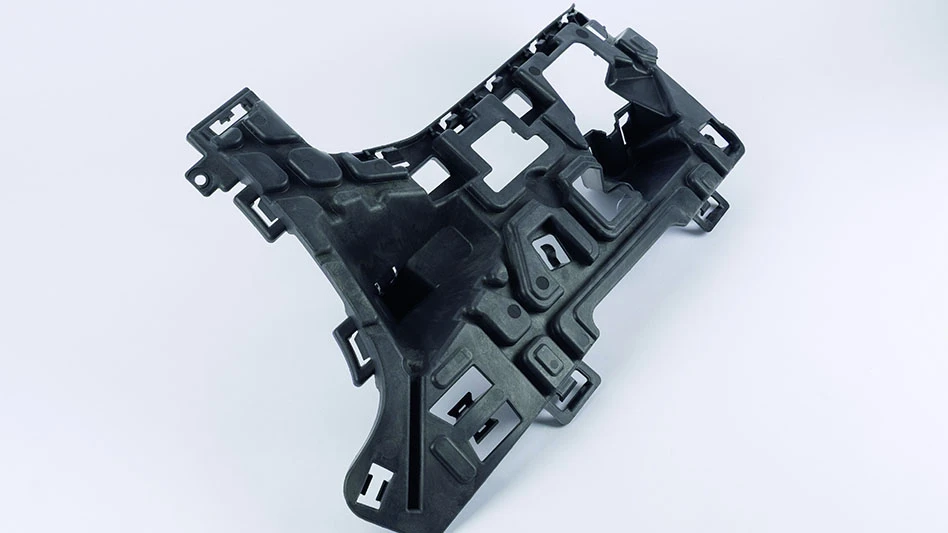

Austria-based Borealis GmbH says a global vehicle manufacturer has selected two of its recycled-content Borcycle M polypropylene (PP) resins for use in the production of automotive bumper brackets.

The automaker is using Borcycle MD2550SY and Borcycle GD3600S advanced mechanically recycled resins for the bumper brackets of an SUV. The company says both grades incorporate high levels of postconsumer recycled (PCR) content (50 percent and 65 percent, respectively) and are produced in facilities certified by the RecyClass organization.

The company says both grades meet “strict standards for consistency and purity, providing excellent processability, performance and quality, together with a significantly lower CO₂ footprint than comparable virgin materials.”

Borealis says its Borcycle GD3600SY product successfully has been used in steady production since 2024, including in interior applications.

“This is another example of how our Borcycle M portfolio helps automotive manufacturers integrate mechanically recycled content into demanding structural parts with confidence,” the firm says.

“Through these solutions, we’re helping our customers move closer to their sustainability targets and prepare for the European Union’s forthcoming end-of-life vehicle regulation, which will set binding recycled content targets across the sector."

Latest from Recycling Today

- ArcelorMittal finishes 2025 with profitable quarter

- Aurubis earnings drop in late 2025

- Yale feature emphasizes pedestrian safety

- In memoriam: Marcel Braud

- PCA sees improving box demand in latest earnings report

- S&P Global Energy Aluminum Symposium 2026: Debating scrap export policy

- Graphic Packaging CEO: ‘External environment remains challenged near term’

- Recycling Today Media Group, NWRA launch new Safety First webinar series