Bee’ah, an environmental managemetn company headquartered in Sharjah, United Arab Emirate (UAE), has selected Oregon, USA-based Bulk Handling Systems (BHS) to design, engineer, manufacture and install a major retrofit to the company’s Sharjah material recovery facility (MRF). The facility is currently the largest in the Middle East, with the capacity to process more than 500,000 tonnes of municipal solid waste (MSW) annually. The retrofit, scheduled to be operational in early 2017, will upgrade capacity and automation to increase recovery and total diversion, BHS says.

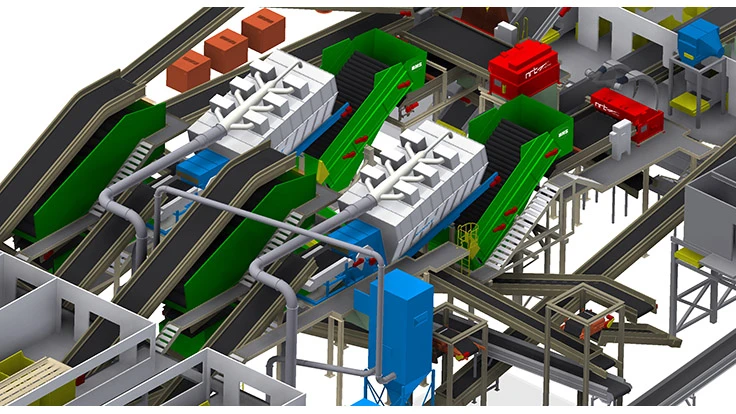

The equipment manufacturer and systems integrator says it will implement its latest and most advanced technologies, including BHS Bag Breakers and Tri-Disc screens, Nihot air separators and NRT In-Flight Sorting brand optical sorters. BHS Tri-Disc screens will replace existing trommel screens to improve separation efficiency, decrease energy consumption and increase throughput, according to the company. BHS screens also will increase the recovery of organic materials by 50% to 600 tonnes per day. The system’s throughput will expand from 68 tonnes per hour (tph) to more than 75 tph, BHS says.

Nihot Single Drum Separators will separate heavy items, such as bulky metals, and inert materials from lighter, high-value recoverables, such as fibre and containers. To increase film recovery by 100%, NRT SpydIR optical sorters will be paired with Nihot rotary air separators, creating the FiberPure film recovery system, BHS says. The FiberPure will detect and eject film, pneumatically conveying it away from the remaining clean fibre stream. The NRT SpydIR optical sorter also is being employed to increase polyethylene terephthalate (PET) recovery by 15%. Magnets and an eddy current separator will increase ferrous and nonferrous recovery by 25%, while the BHS Total Control controls package will integrate pre-existing and new equipment, giving the entire system advanced SCADA (supervisory control and data acquisition) technology.

Commenting on the contract, Daker El Rabaya, managing director of waste processing, treatment and disposal at Bee’ah, says, “BHS is selected according to stringent criteria, including technical know-how and manufacturing experience, to ensure their products, methodological knowledge and business strategies match Bee’ah’s high standards. This agreement reaffirms BHS’ exceptional reputation as high quality manufacturers and experienced integrators of whole system solutions.”

He adds, “We look forward to working closely with our new partners to support our regional expansion and significantly improve our MRF capacity to match our operational growth.”

BHS CEO Steve Miller says, “Over the last decade, Bee’ah has set a new standard defining what is possible with an integrated waste management and recycling plan. Bee’ah’s MRF is one of the largest in the world, and yet they made the decision to invest even further. The technology deployed here will increase automation, throughput and recovery to once again define the new standard.”

Headquartered in Eugene, Oregon, BHS is a leader in the design, engineering, manufacturing and installation of sorting systems and components for the solid waste, recycling, waste-to-energy and construction and demolition industries. Wholly owned subsidiaries include Nihot (Amsterdam), NRT (Nashville, Tennessee) and Zero Waste Energy (Lafayette, California).