Image courtesy of BASF

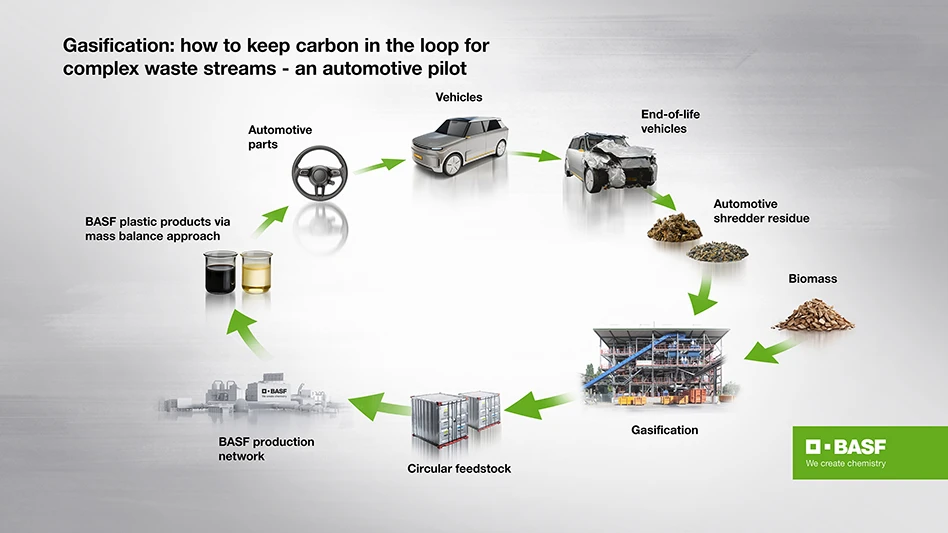

Porsche AG and BASF SE, in collaboration with technology partner Bioenergy and Sustainable Technologies GmbH (BEST), have completed a pilot project that demonstrates the recyclability of high-performance plastics from automotive shredder residues (ASR), a mixture of plastic, film, paint and foam residues, using gasification.

This pilot project validates the viability of new sources of plastics and applications for chemical recycling, the company says, with the ultimate goal being to source less primary material in the future and increase the proportion of recycled materials in vehicles. As part of the project, the chemically recycled material was used to manufacture steering wheels.

“Pilot projects like these allow us to evaluate how we can further develop the circular economy as a sustainability field at Porsche and how we can anchor chemical recycling in our strategy in the long term,” says Robert Kallenberg, head of sustainability at Porsche AG, based in Stuttgart-Zuffenhausen, Germany. “We are testing new recycling technologies with our direct partners in order to increase recyclate quotas, gain access to previously unusable recyclate sources and evaluate new processes for waste streams that are currently being thermally utilized.”

Porsche has set a goal to increase the proportion of verifiable secondary materials in its vehicle production. The pilot project demonstrates that chemically recycling ASR can be a complementary alternative to mechanical recycling and that demand-driven scaling is possible via a mass balance approach.

In this project, a combined material stream consisting of end-of-life automotive material and biomass was recycled in a gasification process. The resulting recycled raw material, the so-called synthesis gas and its derivatives, replaced fossil raw materials in BASF's integrated value chain. Within its production network, BASF then produces the polyurethane formulation needed for the steering wheel using a mass balance approach, the company says.

The process uses modern gasification technology from BEST GmbH, Graz, Austria, to convert plastic and other residues into synthesis gas at high temperatures.

"In our plant, we have previously converted biomass such as wood or straw into chemical raw materials. In this pilot project together with BASF and Porsche, we have now used this gasification technology for the first time to convert complex plastic waste streams together with biomass into synthetic crude oil, known as syncrude," says Matthias Kuba, area manager for Syngas Platform Technologies at BEST. "This form of chemical recycling has great potential for converting complex, mixed waste streams into new, valuable raw materials. It thus represents a sensible alternative to waste incineration."

Martin Jung, president of BASF’s Performance Materials division, says the company offers a wide range of complementary recycling solutions.

“We prioritize mechanical recycling and continuously improve its efficiency. At the same time, the type of waste and the degree of sorting determine which technology is best suited," he says. "We are convinced that complementary technologies such as chemical recycling, which includes pyrolysis, depolymerization and gasification, are necessary to further promote the circular economy and reduce the plastic waste that still ends up in landfills or is incinerated today.

"To optimally utilize the various waste recovery options and further develop all technologies in parallel, the appropriate regulatory framework is essential.”

Latest from Recycling Today

- SSAB finishes 2025 with decreased revenue

- Vecoplan appoints CFO

- Aurubis raises full-year forecast

- Levitated Metals adds LIBS sorting technology

- Redwood Materials closes on $425M in Series E financing

- Updated: Wieland Chase expands northwest Ohio facility

- Recovered paper traders report lukewarm market

- SHFE trading expansion focuses on nickel