Editor's note: Tony Efros, who was interviewed for this story, is no longer with the company.

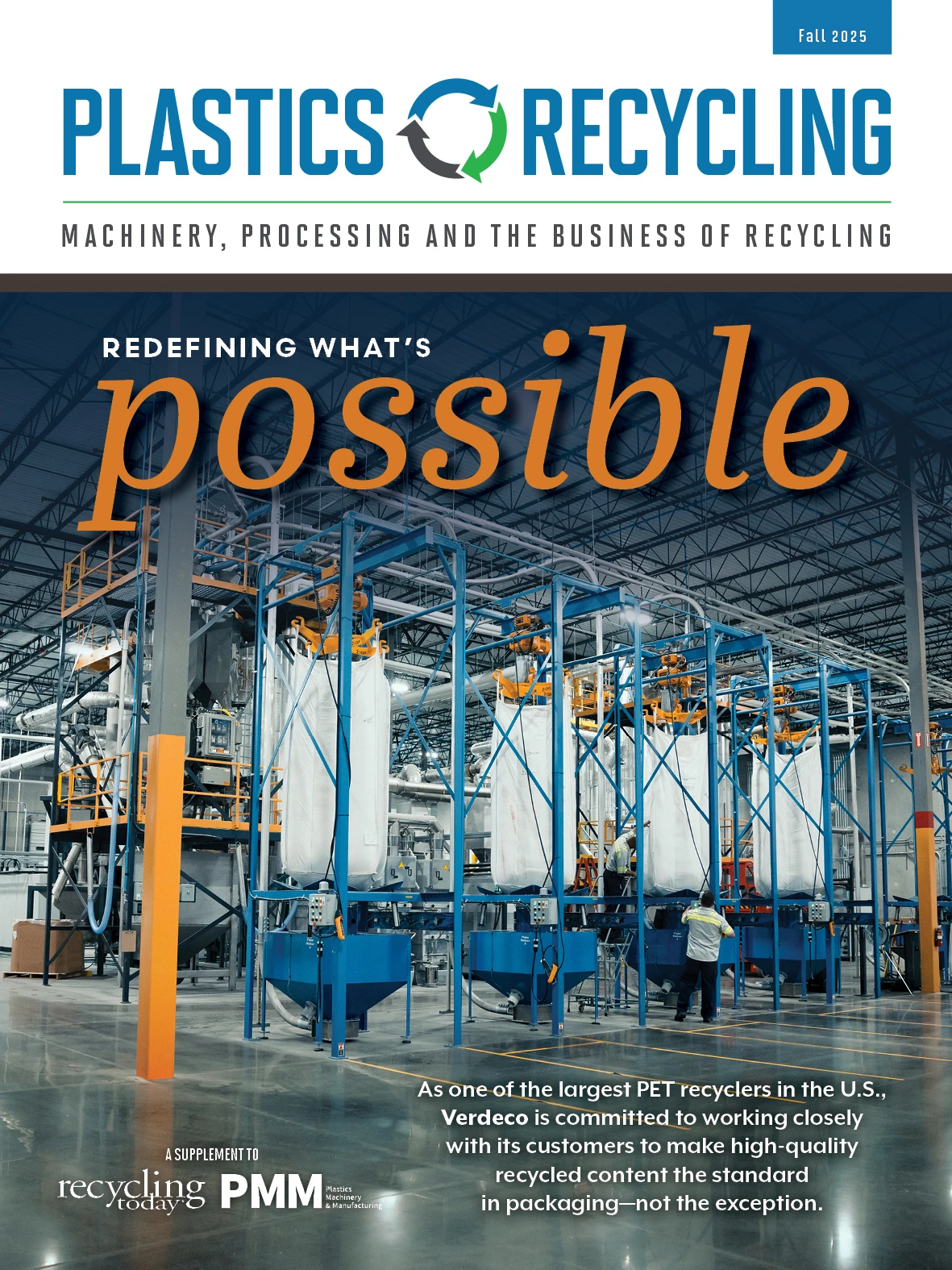

Verdeco views its mission as a simple one—to make high-quality recycled polyethylene terephthalate (rPET) the standard in packaging while helping brands meet sustainability goals and deliver products consumers can trust.

To achieve that goal, the Piedmont, South Carolina-based recycler develops customized food-grade rPET pellets at three facilities strategically located throughout the United States and fosters a customer-centric culture, ensuring every product it makes solves real-world challenges for the companies and brands it works with.

“We are customer-centric and quality-driven,” says Tony Efros, Verdeco’s director of sales and procurement. “We’re putting a huge focus on quality. We are always looking for ways to improve, and we’re in daily communications with our customers on what we can do better for what they need.”

Nationwide expansion

Verdeco was founded in 2011, operating out of a facility in South Gate, California, in Los Angeles County.

Since then, the company has created coast-to-coast reach by expanding to three production facilities with the addition of sites in Terre Haute, Indiana, and, most recently, in Piedmont. In total, Verdeco currently employs 105 people who comprise its production, technical and corporate staff.

The 217,000-square-foot Piedmont location opened its doors in 2023 and serves as the company’s headquarters while also housing its Innovation Center, a research and development (R&D) hub where it can quickly test and validate its customized pellets at pilot-scale for customers.

Considered one of the largest rPET producers in the U.S., Verdeco has a combined annual capacity of approximately 243 million pounds, with the space to add even more at the Piedmont facility in the future. Efros says the company sources washed flake globally from a diversified, verified supplier network. Material is carefully vetted to ensure consistent quality and supply for the company’s customized products.

“We’re procuring hot-washed clear flakes from around the globe,” he says. “It depends on the quality of the material, the customer needs and the specifications of the end product. If we look at the West Coast, for example, we will look for Grade-A [material]. If we look globally, we will look for better quality, [as other countries] don’t really classify it as Grade-A.

“There is a direct connection between our feedstock and our finished product, so it depends on our customers’ needs and preferences, and then we’re doing the match between the two.”

Creating the right pellet

Each of Verdeco’s three facilities uses two processing lines to turn hot-washed PET flakes into pellets.

To get there, flakes first run through melt filtration and extrusion, followed by pelletizing. Next, pellets undergo solid-state polycondensation to improve their viscosity and strength while mitigating contamination. Finally, they head to a quality control stage where the company checks for quality, safety and performance.

“We hold ourselves to the highest standards of safety, quality and performance in every aspect of our business,” Verdeco tells Plastics Recycling.

Through its rigorous process, Verdeco is able to produce pellets for use in a wide range of packaging. Its Kleer rPET can be used in bottles, containers, film, trays, tubes and more. It also offers:

- Heet, a hot-fill packaging solution for alcoholic beverages, juice, marinades, sauces, soda and tea.

- Ayr, which are pellets for extrusion blow-molded products like packaging for automotive components, juice, milk and water bottles and plastic drums.

- Thyn, a material to be used in thin-walled packaging such as containers and trays.

The company also offers toll processing, taking customers’ rPET flakes and turning them into custom rPET pellets for use in different projects.

“This approach reduces risk from both sides,” Efros says of the company’s toll processing capability. “It helps with the commercialization [of packaging products], and it’s helping us bring the finished product to the market much faster.

“Because of our capacity of 240-plus million pounds, we need to deliver customized solutions to the customers and cover a wide range of applications. Having this scale and science combination with our customers, that’s what helps us cover all of the 240 million pounds. It depends also on the applications of the customers. We’re super proud of the PCR [postconsumer resin] goals our customers have in place, and we’re increasing the amount of applications [we develop rPET for] to help them reach those goals.”

Setting itself apart

Verdeco’s Innovation Center, located within its Piedmont headquarters, is helping it carve out a unique position in the industry thanks to its robust capabilities.

With six dedicated employees, the company describes its R&D arm as highly application-driven. The department uses analytical testing, a pilot-scale production line and the ability to tailor custom pellet formulations for each customer. At the Innovation Center, workers can test intrinsic viscosity, colors, clarity and haze while creating customized hot-fill, thin-wall and extrusion blow molding applications.

Efros says the company validates its formulations by producing sample bottles or plaques in-house and offers same-day testing of that material.

“That helps us speed up all the trials and all the special applications that we’re doing for our customers,” he says. “It’s basically reinforcing our customer-centric culture. … That calibration is the center of our model, our day-to-day philosophy.”

The facility’s location in South Carolina was strategic, according to the company.

“From an import standpoint, it puts us closer to several major ports and was based on its proximity to major customers,” Efros says. “It also is a very strong talent pool area. There are lots of great universities here, it’s a business-friendly environment, and we believe we can attract skilled employees in this area.”

Verdeco already has linked up with area universities such as Clemson and Furman to participate in events and help students gain work experience.

“It’s also interesting for the universities, for their classes, where they can also partner with us for tours at our facility and even work for us after they graduate,” Efros says.

Viewing the market

The current rPET market presents several challenges, according to Efros, starting with feedstock supply.

“We are dealing with postconsumer flake that is less consistent in quality and availability and there is more testing required,” he says. “We do our testing and our investing in the procurement process to ensure we’re buying what works for our customers and their industries.”

Efros says another challenge lies in the complexity of qualifications for customers. Since they are food-grade qualifications, they require extensive testing that can slow adoption. Also, the volatility in pricing and bale indexes throughout different seasons can be difficult to navigate as recycled resin prices move with bale prices and virgin PET spreads, making contracts and operational efficiency critical to reliable supply.

“We’re addressing it by doing the procurement smarter and working better on that side,” Efros says.

However, Efros recognizes there are opportunities in the space despite those challenges.

“There are opportunities with the tools we have at Verdeco to go after premium applications, not only water bottles,” Efros says. “We can go for hot-fill applications, clear packaging, extrusion blow molding and thin-wall containers. We can address it and get the additional volume and replace virgin PET that is used in those industries right now.”

He points to increasing recycled-content mandates and corporate sustainability goals as another opportunity to drive demand for consistent, high-quality rPET.

“We want to make sure we’re well-established and well-positioned for the additional demand that will scale in the near future,” he says. “I’m excited that we have three locations in the U.S. It’s super important for us and our customers.

“We’re doing the right thing, and we’re doing it in the U.S. We want to continue to provide high-quality material to our customers, and as we scale up with them, we can create more jobs, more facilities similar to what we have now, and make everything in the U.S. That’s our main focus.”

Explore the Fall 2025 Plastics Recycling Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- International Paper completes sale of global cellulose fibers business

- Building a bridge to circularity

- Alton Steel to cease operations

- Nucor finishes 2025 with 14 percent earnings decline

- Algoma to supply Korean shipbuilder

- Improving fleet maintenance management across multiple locations

- Aimplas project recycles nylon fishing nets

- New Ineos Recycl-In product made with 70 percent recycled content