One of the various challenges faced when processing scrap metal is the potential for incoming loads to contain radioactive materials. The consequences of not catching these materials early in the process can be dire and result in a very costly cleanup effort.

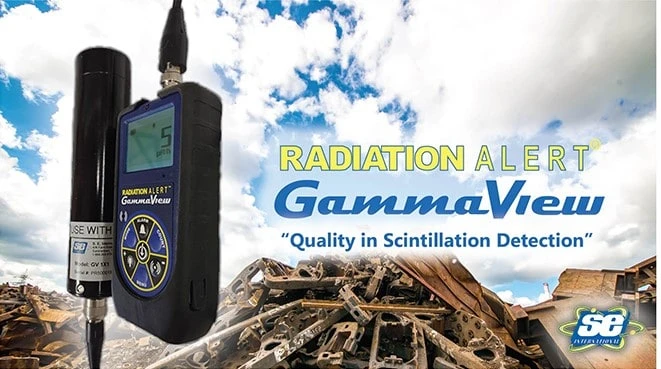

This includes the tricky hunt for the source of contamination after the initial alarm is raised. Having quality instrumentation to help can be the difference between a relatively smooth operation and a rocky road with many potholes. This is when the Radiation Alert GammaView from S.E. International Inc. comes in handy. Its intelligent design, accompanied by high levels of sensitivity and accuracy, makes it ideal for circumstances such as these.

Radioactive contamination of scrap metal can occur for a variety of reasons. Most of the time it’s the result of small amounts of contaminated material being improperly disposed of. This could be due to not being labeled correctly or a lack of awareness about what’s being discarded.

Either way, the result is the same, and companies end up with an entire load that needs to be rejected. Even though finding these materials can be hard, it’s better to do it when it first arrives at a facility than to discover it further along in the process. Processing radioactive materials unknowingly brings the potential for cross-contamination with much of the inventory. Cleanup can be costly and dangerous as operators risk exposing workers to radiation.

Most of the time, a piece of contaminated material is discovered by the large portal monitors that scan the incoming trucks first. Once an issue has been confirmed, further inspection with a hand-held survey meter can help pinpoint the exact location of the radiation source.

Companies will begin their surveys by establishing a background count. Normal background radiation levels vary at different locations, different times and in different areas of the same room. To accurately interpret the readings you get, it is good to establish normal background radiation counts for each area the company plans to monitor.

The GammaView is intuitive and makes this task a simple process of navigating the easy-to-use interface. Directions for performing a timed count are readily accessible in the operations manual and on our website. After the company has determined normal background for its area, scanning can begin.

The operator needs to get close to the object being surveyed without contaminating the detector. The GammaView comes equipped with a highly sensitive sodium iodide detector. This determines the appropriate distance with greater ease and accuracy.

After determining the correct distance to start, the scan can begin. Generally, operators will want to move the detector no more than 2-3 inches per second, all the while making sure to pass over as much of the area to ensure that nothing is missed. The ergonomic compact design and portability of the GammaView make it ideal when performing a task of this nature.

While scanning, operators can listen to the beeper and view the counts on the graphic display to determine if any levels are above average background. The device will chirp faster when high levels of radiation are detected. The counts displayed on the unit will also increase in value. The GammaView’s graphic display is easy to read and comes with a backlight function.

The Radiation Alert GammaView was designed to tackle these events in a way that alleviates some of the pitfalls of radiation surveying. For more information, click here or call 931-964-3561.

Latest from Recycling Today

- ReMA lobbies for shredder wear parts tariff exclusion

- Dow, Gruppo Fiori develop recycling pathway for automotive polyurethane foam

- Ascend produces recycled lithium carbonate from used LIBs

- RecycLiCo acquires building to serve as corporate HQ, operational hub

- EZVIZ partners with Plastic Bank

- Radius, under new ownership, replaces CEO

- SMS in Illinois sells assets to equity investor

- Mayr-Melnhof reports earnings growth so far in 2025