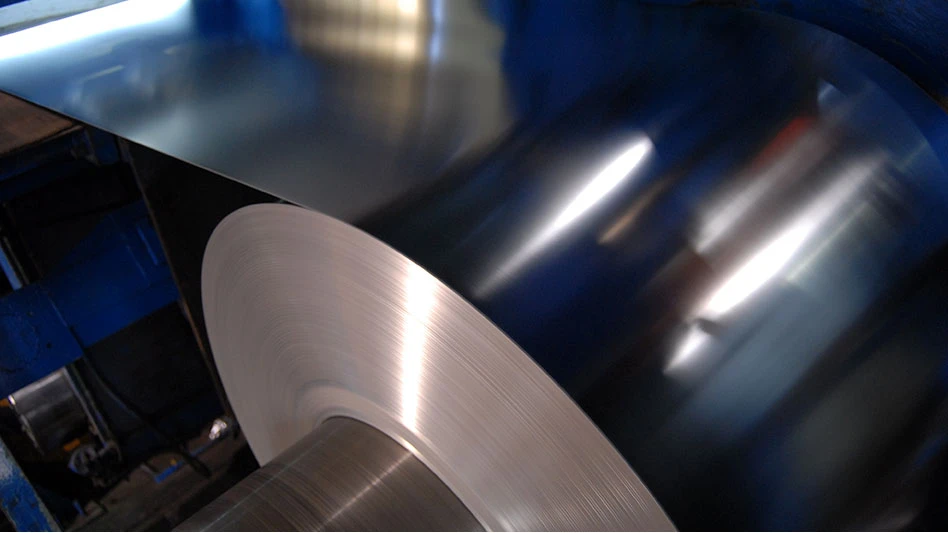

Photo by Recycling Today staff.

Global steel production in the 64 countries reporting to the Brussels-based World Steel Association (Worldsteel) was 142.7 million metric tons this February, which the association says represents a 5.7 percent decrease compared with February 2021.

Year to date, China remains the nation with the largest year-on-year decrease, having produced 10 percent less steel in the first two months of 2022 compared with last year. In the financial press, declining activity and financial distress in the property market in China are receiving much of the blame for the lack of steel demand there.

Joining China in the negative ranks are neighboring nations South Korea (-2.6 percent) and Japan (-2.2 percent).

The cutbacks are not restricted to Asia, however, as Brazil has thus far produced 5.8 percent less steel compared with early 2021. Perhaps of more direct interest to United States scrap processors, Turkey’s output also has fallen this year, by 5.7 percent in the first two months.

At the other extreme is India, which has produced 6.6 percent more steel in the first two months of this year compared with early 2021, according to Worldsteel.

Output in the United States and Europe, meanwhile, has been closer to stable. In the U.S., the 13.4 million metric tons produced this January and February represent just a 0.6 percent increase year-on-year. Western Europe’s largest steel producer, Germany, has produced 1.1 percent more steel in early 2022 compared with last year.

Industry observers are likely to take an interest in Russia’s steel output going forward. In the first two months of the year, that nation’s mills produced 12.4 million metric tons, or 1 percent more than in early 2021. That, however, was before a sizable list of nations began placing widespread sanctions on Russia and its exports, materials and corporations.

Latest from Recycling Today

- Nucor names new president

- DOE rare earths funding is open to recyclers

- Design for Recycling Resolution introduced

- PetStar PET recycling plant expands

- Iron Bull addresses scrap handling needs with custom hoppers

- REgroup, CP Group to build advanced MRF in Nova Scotia

- Oregon county expands options for hard-to-recycling items

- Flexible plastic packaging initiative launches in Canada