GBB to Provide C&D Recycling Consulting for North Carolina Project

Gershman, Brickner & Bratton Inc. (GBB), Fairfax, Va., has been selected by the North Carolina Turnpike Authority, as part of the Currituck Development Group, to provide construction and demolition debris recycling consulting services for the Mid-Currituck Bridge project, a 7-mile bridge in North Carolina’s Outer Banks.

One of the project’s goals is to find a use, either on site or elsewhere, for the C&D debris generated by the project. GBB, will inventory the origin, type and quantities of all materials projected to be generated, including buildings, vehicles and road materials to be removed. A specific waste management plan, including reuse and recycling opportunities and in some cases, disposal requirements, will be developed for each primary constituent material.

"GBB will also evaluate all construction materials needed for the project and incorporate on-site C&D materials wherever feasible," says Bob Brickner, GBB executive vice president. "Typical examples include the grinding and processing of old concrete and asphalt materials into spec materials for reuse as base aggregate materials and/or recycled asphalt pavement that can be easily incorporated into roadways, bike paths, walkways and parking areas."

Less typical examples include supplying project materials to third-party firms that conduct metals recycling, asphalt shingle processing for reuse in new asphalt materials, gypsum scrap processing and gypsum recycling for soil amendments, wood grinding for mulch product generation, tire grinding for tire-derived fuel generation, used wire recycling and the use of mechanical systems for full scale processing and sorting of mixed C&D materials to increase recycling opportunities.

In addition, GBB will seek to reduce local stockpiles of recycled materials when and where it is feasible to do so. Being familiar with C&D processors in eastern North Carolina and southeastern Virginia, the team will pursue opportunities to use third-party-generated recycled materials for various aspects of the project. With a very good working relationship with North Carolina regulatory officials, GBB will maintain communication throughout the project so that any additional entities that obtain operating permits that could enhance the use of recycled materials will be identified and considered as the project evolves.

C&D Facility to Open in Southwestern Florida

The owners of Reliable Roll-Off, Naples, Fla., have decided to build a construction and demolition recycling facility in Bonita, Fla.

Richard Smith, a partner in Reliable, says the company’s owners saw a need for a C&D recycling facility in the area. The company has been offering roll-off services for nearly three years.

After meeting with several local and county government officials, the company decided to build a facility that would take in and process the recyclables coming from the roll-off containers it already was hauling.

Smith says the plant is in the process of obtaining operating permits and could break ground on a building by spring 2009. The building will measure approximately 24,000 square feet.

Smith says he hopes the 2.5-acre facility will begin taking in material by early 2010. It is designed to be able to handle 500 tons of material per day.

The company also has been in discussions with equipment manufacturers to provide equipment that will be used to process the collected material.

One piece of equipment the company will focus on is a grinder, which will allow the company to make a compostable material from some green debris, wood and even gypsum.

Smith says the company also will process OCC (old corrugated containers), most grades of metal and plastics. He estimates that 70 percent of the material delivered to the facility will be recycled.

Universal Wrecking Completes Selective Demolition Project in Maryland

Universal Wrecking Corp., a demolition, scrap metal recycling and wrecking contractor based in Brick, N.J., has completed the selective demolition of a fire-damaged building in Maryland.

Sponsored Content

Screen Smarter, Process Faster with GK’s FINGER-SCREEN FreeFlow™!

Upgrade to the next level of material separation with the FINER-SCREEN FreeFlow™ —built for efficiency, durability, and maximum throughput. With no bottom pan to clog, it handles bulky and wet materials effortlessly. Minimize jams, maximize uptime, and boost productivity. Optimize your operation today!

Sponsored Content

Screen Smarter, Process Faster with GK’s FINGER-SCREEN FreeFlow™!

Upgrade to the next level of material separation with the FINER-SCREEN FreeFlow™ —built for efficiency, durability, and maximum throughput. With no bottom pan to clog, it handles bulky and wet materials effortlessly. Minimize jams, maximize uptime, and boost productivity. Optimize your operation today!

Sponsored Content

Screen Smarter, Process Faster with GK’s FINGER-SCREEN FreeFlow™!

Upgrade to the next level of material separation with the FINER-SCREEN FreeFlow™ —built for efficiency, durability, and maximum throughput. With no bottom pan to clog, it handles bulky and wet materials effortlessly. Minimize jams, maximize uptime, and boost productivity. Optimize your operation today!

Sponsored Content

Screen Smarter, Process Faster with GK’s FINGER-SCREEN FreeFlow™!

Upgrade to the next level of material separation with the FINER-SCREEN FreeFlow™ —built for efficiency, durability, and maximum throughput. With no bottom pan to clog, it handles bulky and wet materials effortlessly. Minimize jams, maximize uptime, and boost productivity. Optimize your operation today!

Sponsored Content

Screen Smarter, Process Faster with GK’s FINGER-SCREEN FreeFlow™!

Upgrade to the next level of material separation with the FINER-SCREEN FreeFlow™ —built for efficiency, durability, and maximum throughput. With no bottom pan to clog, it handles bulky and wet materials effortlessly. Minimize jams, maximize uptime, and boost productivity. Optimize your operation today!

Sponsored Content

Screen Smarter, Process Faster with GK’s FINGER-SCREEN FreeFlow™!

Upgrade to the next level of material separation with the FINER-SCREEN FreeFlow™ —built for efficiency, durability, and maximum throughput. With no bottom pan to clog, it handles bulky and wet materials effortlessly. Minimize jams, maximize uptime, and boost productivity. Optimize your operation today!

During a severe storm many years ago, the building was struck by lighting and subsequently caught fire. The building sat vacant for several years while the owners and insurance companies determined the best course for reoccupying the building.

After a thorough engineering evaluation, it was determined that a majority of the building could be saved and rebuilt using the existing structures and foundations.

Universal Wrecking Corp. (UWC) was contracted to provide selective demolition services in light of its extensive experience with fire and storm damaged structures as well as its commitment to an aggressive schedule and a competitive bid price.

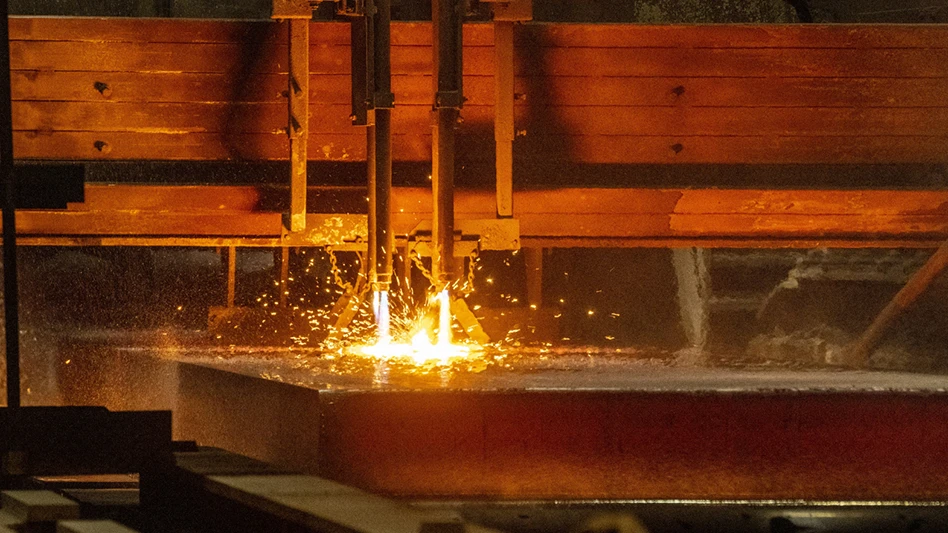

UWC had to achieve several goals to perform the demolition phase of the project to the client’s specifications. First and foremost, the structure had to be gutted in a safe manner. Because of existing structural damage, UWC had to carefully perform interior demolition services with strict attention to employee and equipment safety. Another requirement was to carefully remove the structurally damaged areas while not damaging sound areas. This surgical removal was carefully executed by using UWC’s experienced demolition crews as well as specialized demolition equipment. UWC used skid steers with demolition buckets as well as laborers in man lifts with demolition saws and torches. Finally, the structurally sound steel truss roof sections needed to be cleaned of debris and roofing materials while leaving the structural metal beams intact. UWC again used the specialized demolition equipment and trained crews to carefully remove the unwanted debris while not damaging the structural members.

UWC made every attempt to recycle as much as possible throughout the project. Scrap metals generated were sent off site to be recycled. Concrete and masonry block was sent off site to a concrete recycler.

Universal Wrecking Corp. offers a variety of demolition services, including commercial and industrial demolition, interior demolition and scrap metal recycling.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the April 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- NDA unveils workforce toolbox

- Ineos Styrolution launches sour cream cups made with recycled PS

- Lacerta products receive PCR certification

- Trash Pandas Utah launches dumpster rental service

- Vesper added to ReMA’s ISRI Specifications

- Comstock purchases equipment for commercial-scale solar panel recycling site

- LKQ to sell its self-service segment

- BMRA: Potential recovered steel export restrictions risk collapsing UK metals recycling industry